There are 9 Wastes in the Lean Waste Wheel

When we think about improving operations and the Lean waste wheel, how many Lean wastes are there really? Correct Answer: At least 9.

This is in reference to the original 7 wastes in Taiichi Ohno described in his iconic waste wheel, shown below. It’s a question that comes up from time to time and one that Lean aficionados like to debate. Apparently there are tightly-held beliefs on this topic. I say, let’s not over complicate something that Ohno intended to be quite simple. But because waste is the red thread that runs through all of Lean, it’s worth consideration.

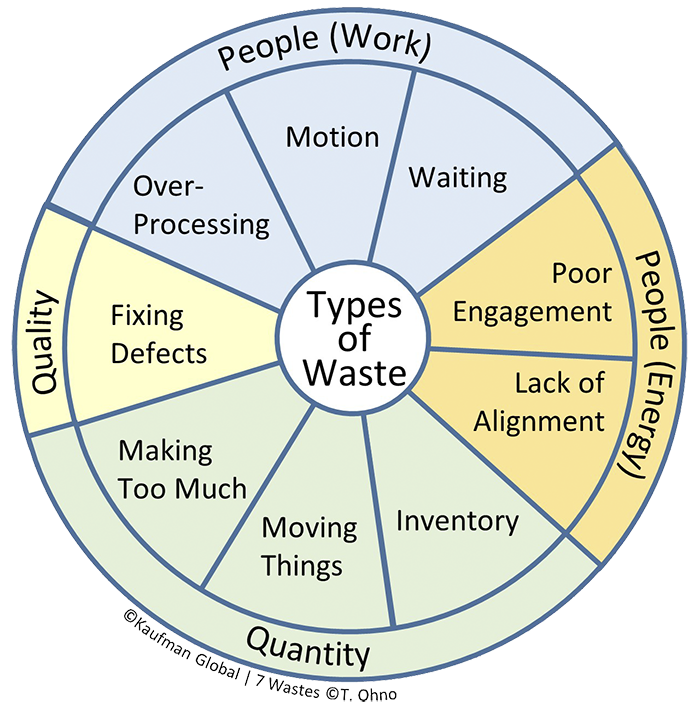

What we now know, is that there are actually 9 wastes in the Lean waste wheel. I know, I know – some who read this will be offended at first. So be it. I am confident that Taiichi Ohno would be open to this continuous improvement, even in the core of his philosophy. I also suspect he would be offended at the amount of waste generated debating the issue.

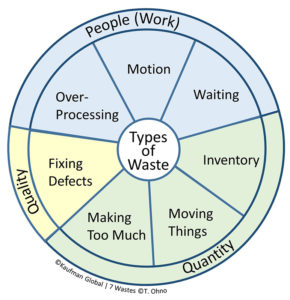

The Lean Waste Wheel – Traditional Version

Ohno’s Iconic waste wheel with the wastes spelled out and categorized – Kaufman Global’s preferred format.

Purists will tell you that there are 7 wastes as described by the sensei and there shall be only 7 wastes. Period. Another faction makes the argument for adding the “waste of people’s intellect” or something similar. This notion has become increasingly popular over the years. Kaufman Global added it long ago, but I’ve always found the classification a bit difficult. Is it intellect, human potential, creativity, insight, involvement, or what? Unlike Ohno’s original 7, these descriptors related to people’s energy seem too variable, too abstract and too difficult to attach to an action. More precision here would be helpful.

The case for waste of intellect arose from the observation that bosses and managers sometimes treat people like cogs instead of active participants in value creation. Ohno’s writings illustrate his own struggles to help us understand the important role of humans in all Lean equations. Who knows why he didn’t include something about people in his original wheel work? Maybe he considered himself an under-cover organizational engineer but felt most comfortable attending to hard assets (inventory and machines) and direct labor (the worker on the floor). Or maybe he didn’t want to too openly point out that management (aka Mr. Toyoda) was missing the point? Or maybe the culture he was dealing with valued the human element without having to spell it out – I doubt this, but it’s possible.

The Most Basic Element of All Waste is Time

With Lean, time is incorporated in many ways: cycle time, value added time, non-value added time, downtime, uptime, etc. Ohno simply broke it down in a way that made it easy to identify obvious targets to be addressed with appropriate techniques. Time is often thought of in terms of efficiency, but effectiveness – which is a way to describe the quality of a process – is a precursor of efficiency.

Waste can be subdivided many ways. My take: It doesn’t really matter how many wastes you want to include. If you think there are 20 different types of waste and this helps attack any one of them better; go for it – whatever works where you are. In the name of continuous improvement we must be willing to add or subtract in order to improve the system, right? Yes. Be careful though. We like to think categorically so more choices makes organizaing more difficult. And too many choices seems somehow less lean.

People Energy, Alignment and Engagement

Which brings us back to the concept of the waste of people’s intellect. When it comes to achieving operational excellence, a tremendous amount of time is lost by failing to engage people doing their daily work. Non-inclusion results in false starts, half measures, low sustainment and do-overs. Workshops and Kaizen Events may be common, but sustainable results are only achieved when people are tangibly connected to everyday improvement.

The Lean Waste Wheel with 9 Lean Wastes

Alignment

Any attempt to be operationally excellent means real and sometimes uncomfortable change; which always meets resistance in some form. Alignment is about getting mostly everyone to support new ways of work. This is a cascading process where actions are different depending on ones place in the organization. If there was only one choice about what to align on however, it would be the need to engage people. The idea of defining people energy waste in specific terms, makes it easier to develop counter measures and a way of thinking about solving this problem that is similar to the other wastes in the wheel.

Engagement

Engagement means giving people a voice in the work they do and holding them accountable for improving things. Achieving broad engagement up and down the organization is tough for many. Kaufman Global uses structures like the Executive Steering Team, the Lean Daily Management System® (LDMS®), and Procedural Action Teams to create an environment that enables engagement. They’re simple enough to understand and do too. If methods are overly complicated, they are easier avoid.

When it comes to waste, everything revolves around time but it’s okay to define as many subdivisions as you like. If you had two to choose, I’d recommend lack of alignment and poor engagement as huge time wasters – possibly the most detrimental to any Lean system. When you get these right, smart people working together toward a common goal always solve the other problems.

**********

Notes:

- Muda is the Japanese term for waste. This is the word Taiichi Ohno would have used.

- A simple definition of waste is: Anything an all knowing, all seeing customer would not be willing to support (pay for).

If you want to learn more about Kaufman Global’s approach to engagement and alignment, check out SLIM-IT, Procedural Adherence and Lean Daily Management System. For a deep dive into the waste wheel and how it applies to Lean, check out our White Paper: Implementing Lean Manufacturing.