Businesses are accountable to ensure the health and safety of employees and customers. This means things like wearing a mask and social distancing during a pandemic. These are the rules, but as we’ve all seen, it’s difficult to follow the rules. In the age of Covid19, the potential to show you care has never been greater. Yet, many businesses are not taking advantage of the opportunity. As people strive to get back into the economy, everyone will remember if they felt safe with you; or not. If any enterprise wants to lock in loyalty now and for years to come, they would do well to pay attention to the current environment and implement appropriate safety practices. We’ve all seen examples of good and bad. So we must ask ourselves:

How do we make good practices, like wearing masks and social distancing, work?

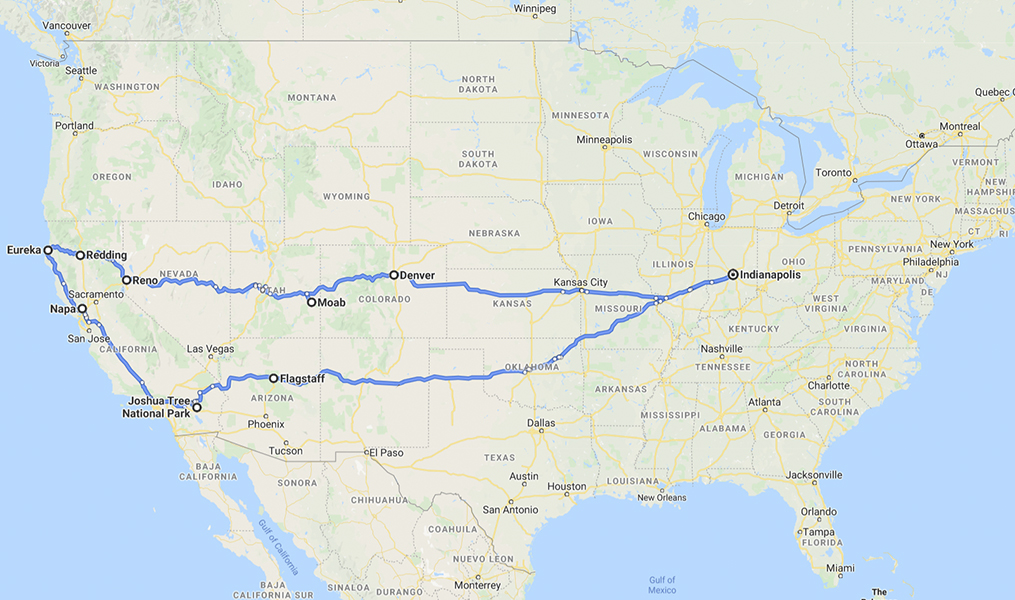

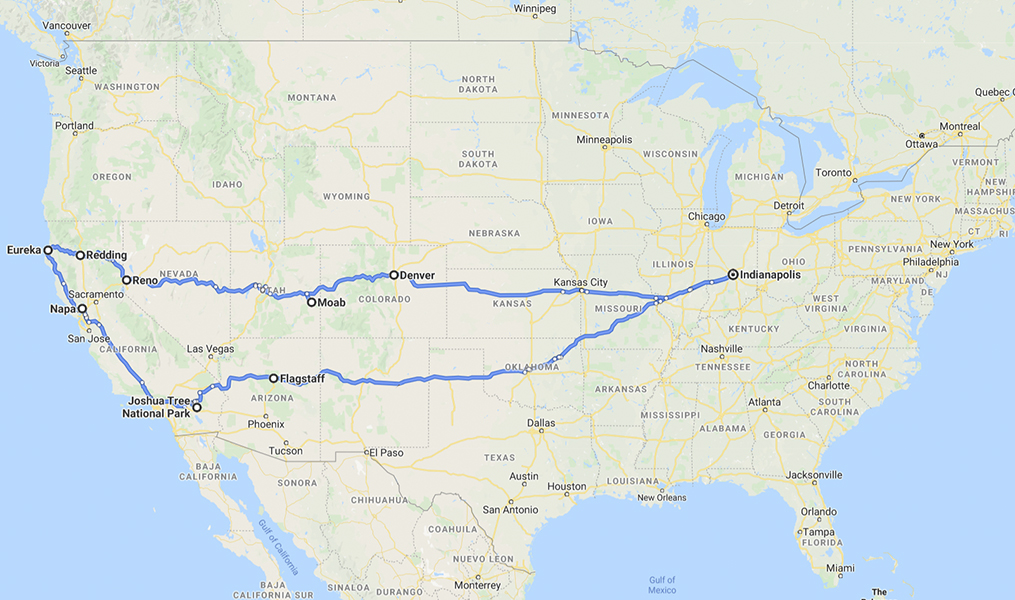

Road Trip!

As with all things, the answer begins with a road trip! During the last week of May and first week of June, I took a 6800 mile (11,000km) road trip across the United States. At this time, quarantine restrictions were being eased. Many places were still closed and a lot of people had not yet ventured out. Yes, I took all sorts of precautions. I wore a mask everywhere, even while refueling. I used alcohol wipes relentlessly, did not enter a single restaurant and minimized grocery stops. I ate all meals in (or near) my SUV, and slept there too for 15 nights.

The Good, The Bad and The Ugly

As you might expect, I saw examples of good and bad Covid19 management practices. Social distancing and masks were prevalent when I stopped briefly for supplies in Oklahoma City and Napa CA. Most of the California coast for 100 miles north of San Francisco was closed, and while some felt this was over-kill, it sends a clear message that danger exists. In fact, along this stretch of highway there were still shelter in place signs up. At almost all of the McDonalds drive throughs the servers wore masks and gloves, credit card readers are presented so no cards are passed back and forth and your meal is given to you on a tray. In Denver, almost everyone was wearing a mask and staying distant in both public places and private businesses.

On the other hand, as I drove through Flagstaff Arizona and Moab Utah, the crowded streets and few masks were a preview of problems to come. In Moab, it felt too risky to even get out of my car. Along the way, more than half the rest areas on the highways were closed due to Covid19. While this may seem like a good way to ensure social distancing, all it really does is make service centers and truck stops even more crowded.

Perhaps the most discomforting situation I encountered was in Redding, California. Of the 150 or so people I saw at three locations (Walmart, Sonic and ampm service station), only about 10 people had their faces covered even though masks were mandatory in much of California at that time. I felt I should have warned them that there was a pandemic in progress because no one seemed aware. It felt unsafe. I had to wonder; do these businesses care about my safety? Do they have a policy or a process? If they don’t, why not? If they have rules, why aren’t they enforced? These seem like logical questions that all businesses should be asking themselves because their employees and customers sure are. (As of July 15, Walmart is requiring masks at all US locations.)

A Big Experiment and Lessons Re-Learned

For Covid19, the use of face masks and social distancing are the best weapons we have right now. These methods and practices are accessible to most everyone. When given a choice, many who could use these techniques choose not to. Until we get a critical mass of people to participate, we will continue the cycle of cases spiking up followed by lock downs and restrictions. And it’s not just the United States. This cycle is in progress around the world.

Without being pedantic, masks and distance slow the transmission of the virus. Less transmission means fewer people get sick and die. It also means more people feel more comfortable being out and engaged in the economy.

The issues related to wide-spread use or non-use of masks and social distancing in response to the pandemic is a lesson about rules and compliance on a scale rarely seen. Similar problems arose during the Spanish Flu, but that was a hundred years ago so this is new for all of us. Well… dealing with a pandemic is new. Issues with people following or not following rules isn’t so new. With so much at stake, it’s worth examining why it’s hard to achieve compliance with even simple things and what can be done about it.

Why Better Procedural Adherence is Important

Foremost; the incalculable cost of health and human lives. A recent meme addressed this issue with this interesting take:

The mistake we made was telling people that wearing a mask would protect others.

Implying that if we believed wearing a mask would help prevent one’s own death, it might lead to better compliance. Sadly, this isn’t true either. But, just a slight increase in uptake would make a difference, so the idea isn’t without merit. The only thing we can conclude is that even an awareness that not wearing a mask could kill you or someone else isn’t enough to compel many.

Then there’s the economic value of reducing the incidence of Covid19. Whether you know someone affected by the disease or not, you are for sure personally affected by the economics of the pandemic. The economy won’t really open up until the majority feels safe within it. We are a long way from that.

The Individual, The Enterprise and The Culture

Survival is the most basic human instinct. People naturally avoid danger. But everyone has a different danger gauge. The notion of danger and safety is subjective. We as individuals evaluate each element differently about what is safe, what is necessary, how much social pressure is tolerable and what we might get away with. We’re dealing with an infinite number of variables. Many people conclude that avoiding danger is the best option and decide that wearing masks and staying some distance from others are reasonable. Not everyone comes to this conclusion.

Because of this disparity, individuals who neither wear masks nor social distance, keep many others away and out of the economy.

Each of us make choices based on our personal biases. If you want to compel a different behavior broadly, you will never do it by convincing everyone it’s the right thing to do. But let’s get beyond the individual for a moment and talk about culture and the enterprise. It is here that the levers of change operate.

Culture and Governments

At the top of the food chain we have culture. Since culture is often associated with countries, we can combine these in a way; recognizing that countries contain many cultures. Where caring social structures that attend to people’s well-being exist, it is easier to apply social pressure for compliance. In other words, if caring about people’s health and safety is highly valued, then people feel more obligated to participate and move toward this social norm.

In places where governments are more willing to establish and enforce rules for dealing with Covid19, the odds for compliance are greater too. Often the work required for enforcement in both the public and private sectors is perceived to be more trouble than its worth. It seems so much easier to side-step the issue so we end up with few standards or even worse; inconsistent and confusing ones. Meanwhile cases and deaths rise while economies crater.

Everywhere around the world has a different mix of these attributes – caring social structures and the willingness or ability to enforce. The United States is at the low end of the spectrum on both counts and therefore experiences high numbers of Covid19 cases. Anywhere that is sort of “squishy” about this will find it difficult to manage the pandemic.

It’s Only Business

We cannot wave a magic wand and change the beliefs and biases of every individual and we can do little to change established cultures. When it comes to rules and compliance, the enterprise / business entity is the best control point. Here, it doesn’t matter whether or not someone believes the requirement’s for entry are good or bad. Products and services and even employment are only available to those who comply. It’s transactional.

If we look at it from a strictly business perspective, its worth noting that:

Those who feel endangered because safety protocols such as masks are being ignored, will stay away and they will remember that their well-being was compromised long after the crisis has subsided.

Employees who are forced to work in what they perceive to be an unsafe environment will at minimum resent it. Yet many businesses default to the lowest common denominator – no mask required, mask optional, or masks required but terrible procedural adherence. This is a bad business decision.

Businesses that don’t take decisive steps to ensure safety and reduce the transmission of Covid19 or are waiting for the government to solve this are missing the point. They have a real opportunity to demonstrate leadership and connect with their employees, customers and suppliers by showing they really care and are willing to make and enforce rules.

How To Have Better Mask Wearing and Social Distancing Compliance

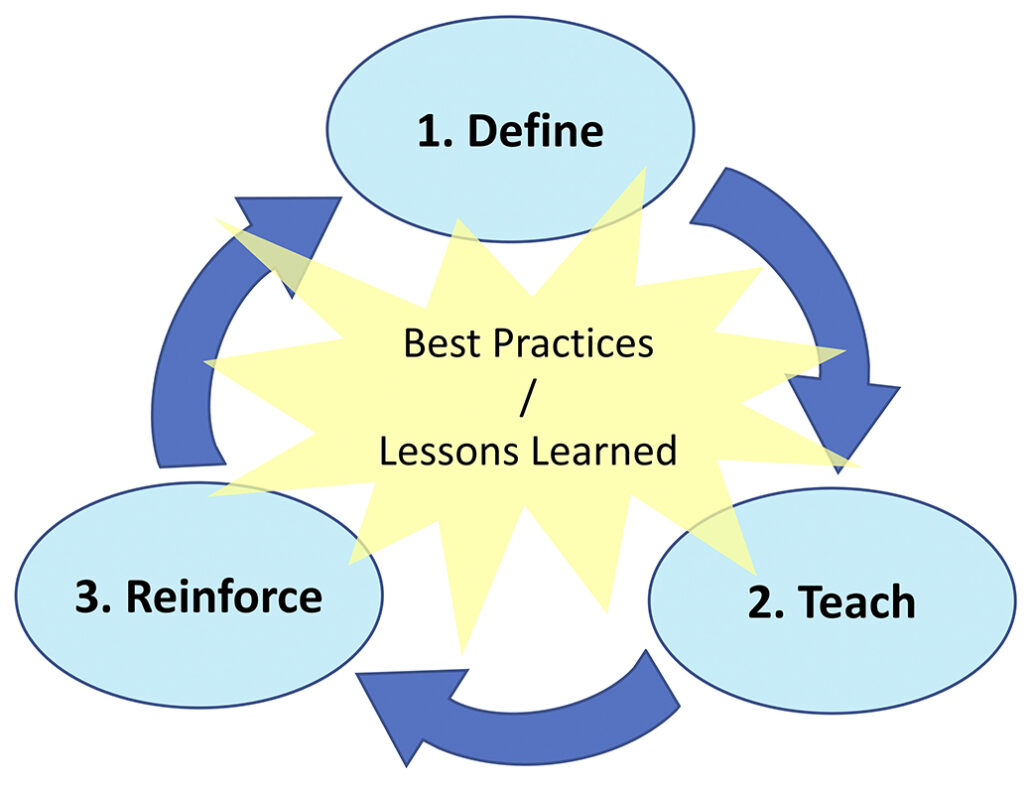

Let’s imagine a business is grappling with the idea of implementing procedures to keep their employees and customers as safe as possible and still conduct business during the pandemic. If the goal is to achieve compliance and get more people to wear masks (correctly, over the nose) and social distance (2 meters between individuals) — three things must happen.

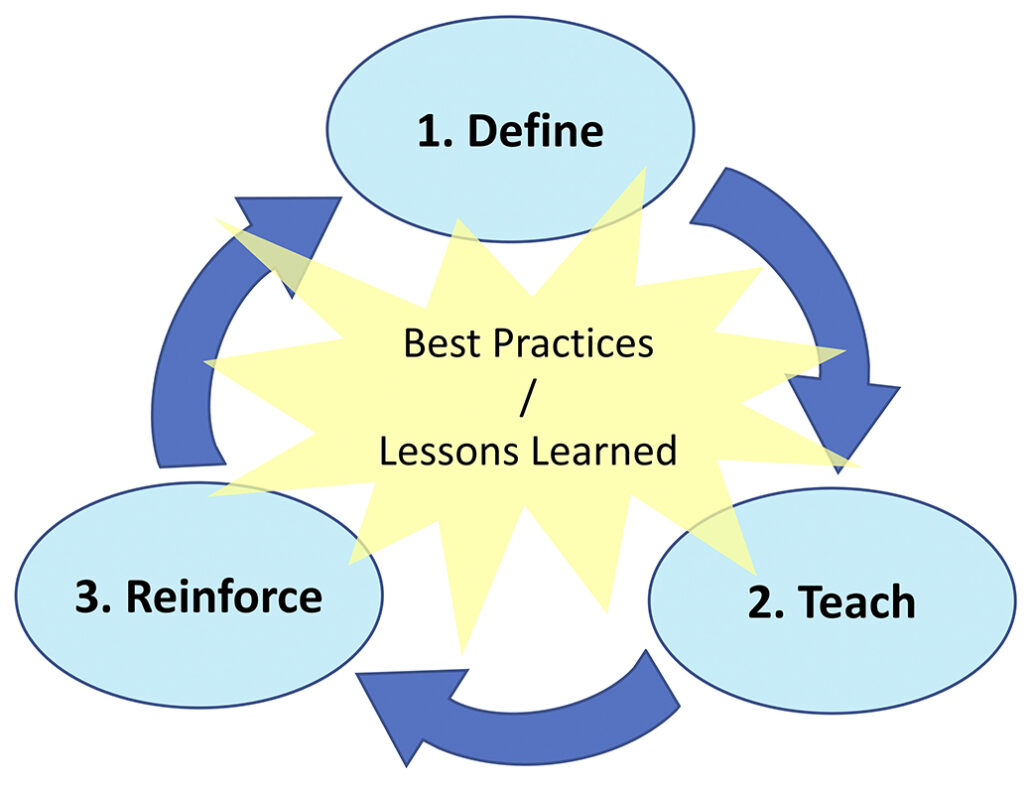

- Define the rules

- Teach the rules

- Reinforce and adjust the rules

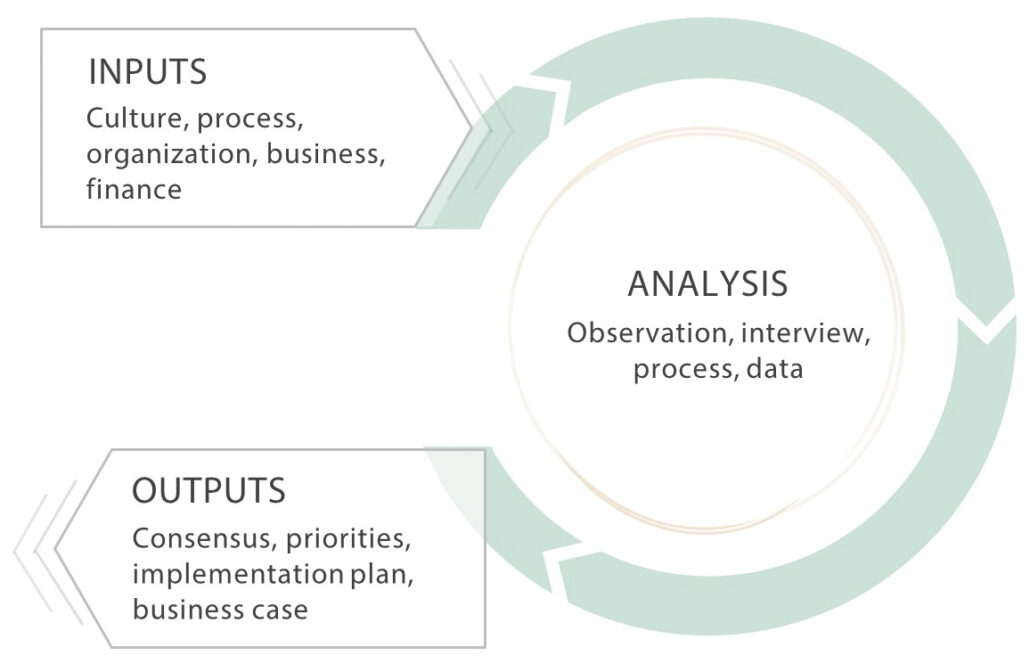

Define: Not guidelines: Rules / requirements. Unambiguous and clear. When they’re violated, mitigation steps must be clearly defined too.

Keep everything as simple as possible. For a single location this is easy enough to do. For a large, multi-national corporation, processes and procedures need to be both global and local. Establishing requirements, how they are going to work and how they will be enforced requires significant process understanding and review cycles. It is essential to involve those working within the processes to gain insight about what really needs to happen.

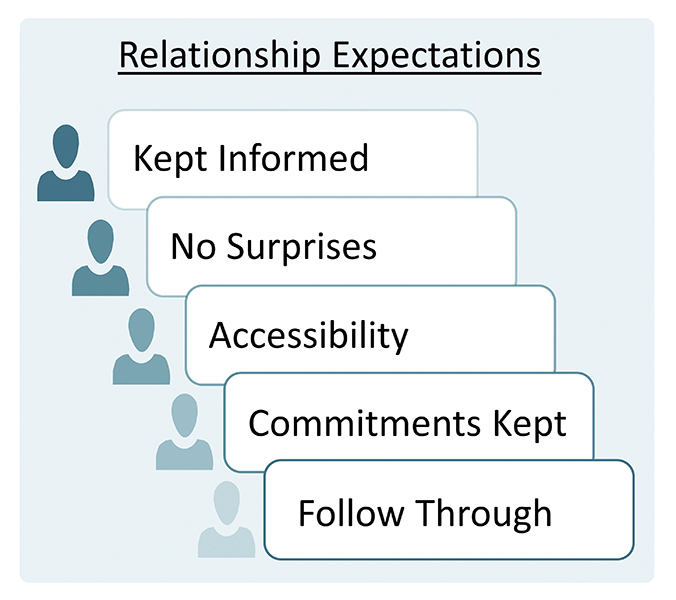

Teach: This doesn’t mean distributing and posting a list of do’s and don’ts. It’s about communication, alignment and refinement through lessons learned. Context is important, particularly for employees. Be clear about why are you asking them to behave in a certain way. For visitors and guests, your objective is to teach as quickly as possible the rules and what is expected of their behavior while visiting.

Visual systems and signs are a great way to teach, but are not enough by themselves. Direct interaction and communication are among your best tools for conveying what’s expected and how to behave inside your business.

Reinforce and adjust: We’re changing people’s behaviors. To accomplish this, we must change our own behaviors. Now is the opportunity to lead by example, model the behaviors and demonstrate your values.

Assuming requirements have been clearly communicated and trained, then we deal with enforcement. This is often where trouble begins because it deals with conflict. Most people prefer to avoid conflict. Having clear and concise processes and procedures, that are well communicated helps with enforcement. To figure this out and develop a standard process, start with “what if” scenarios and establish standard mitigation steps.

Leadership is key here. When there is a violation, it is not ok to look the other way or manifest exceptions. When someone says, “Well, I don’t know, I think it’s ok this time…” you just took 10 steps backwards. Leadership must support those who are following and administering the rules by actively governing:

- Dealing with exceptions. The situation on the ground is always changing. There will be exceptions and new twists. These need to be understood and integrated into the process.

- Communication: Inbound (what’s working and what’s not) and outbound (any changes or lessons learned that need to be spread out).

- Metrics: What are the numbers related to Covid19 safety compliance? What needs attention and where are we performing well and why?

- Status Review: At least one a week. The situation on the ground is changing so fast that anything less won’t work.

The situation is dynamic. It’s ok to adjust the rules. As best practices and lessons learned are identified, they need to be quickly integrated into the three phases noted here: Define, Teach and Reinforce.

Conclusion

There are certainly those who are waiting to see if this thing – Covid19 – just goes away and we can get back to normal. It is painfully obvious that it’s not going away nearly soon enough for businesses to simply tread water. Everything is a choice. Either way you go, people will remember for a long time.

Organizations that take the steps outlined here will get their businesses up and running faster and will forge important connections with their employees, customers and suppliers. They will be doing it in a way that shows that they really do care about the health, safety and well-being of the people within their sphere of influence. In a genuine and business-smart way, they really will be helping to get the economy back on track.

———————

The steps for better compliance outlined here are high-level. If you want to learn more about how to achieve better compliance fast, Kaufman Global can help. For you and me, be safe, wear a mask and social distance.

Apparently, organizations are losing their often stated, but rarely demonstrated, most valuable asset – their people. You can’t open your news feed without seeing an article on The Great Resign. The media has latched onto the idea that workers are leaving their jobs in droves — which is great news for employee engagement survey companies.

Apparently, organizations are losing their often stated, but rarely demonstrated, most valuable asset – their people. You can’t open your news feed without seeing an article on The Great Resign. The media has latched onto the idea that workers are leaving their jobs in droves — which is great news for employee engagement survey companies. Different parts of the world are coming on line at different rates and in direct correlation with decreasing Covid19 cases. That means for example, that Europe is about four months behind the US. Other geographies are slightly ahead or further back for various reasons, mostly related to vaccine access or acceptance. The demand curve will continue to oscillate up in predictable ways, along with the chaos of restarting literally millions of businesses. This syncopated global start-up means the economic tsunami will be roiling around a while – years perhaps. With that comes plenty of uncertainty, along with now obvious problems in supply chains, human resources and constrained capacities.

Different parts of the world are coming on line at different rates and in direct correlation with decreasing Covid19 cases. That means for example, that Europe is about four months behind the US. Other geographies are slightly ahead or further back for various reasons, mostly related to vaccine access or acceptance. The demand curve will continue to oscillate up in predictable ways, along with the chaos of restarting literally millions of businesses. This syncopated global start-up means the economic tsunami will be roiling around a while – years perhaps. With that comes plenty of uncertainty, along with now obvious problems in supply chains, human resources and constrained capacities.