Posts

How to Digitally Enable Performance

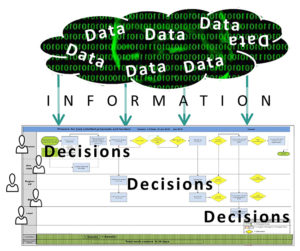

/in Change Management, Digital, Process Excellence /by Jerry TimpsonThe promise of better performance via digitization and real-time access to information is best achieved if we begin with a process-centric view. With that, ask the question: What minimal information does each process require to make the best possible decisions? By so doing, we sort the wheat from the chaff and relay only the information required to speed decisions, enable agility and lift results.

Parse your data thoughtfully to make better decisions faster and get the most out of any process.

We’re impatient. In delivering products and services everybody wants to improve results. Yet, progress rarely matches expectations. To create an advantage, few things hold greater promise than digitization. We’re well equipped with computers, smart phones, tablets and touch screens… and lots of data. The cloud allows us to distribute huge quantities of information with ease. In spite of all this technology, we bog down when it comes to parsing critical bits of information needed to make the people-process interface work best.

What Does Digitally Enabled Change Mean to Performance?

Merging the concepts of “digitally enabled change” and “performance” can mean different things to different people. We’re seldom on the same page. The connection between digitization and performance is two-fold: First, it should enable better and faster decisions; and second, it should help compare results in order to propel best demonstrated practices. Such entitlements are pure gold for a large enterprise. Let’s take a closer look.

- Faster Decisions: If we collect, parse and distribute the right information to the appropriate stakeholders in an environment that’s equipped to use the information, better decisions up and down the value chain are possible. Then, lead times shrink. The ability to reduce lead time is an enterprise’s best indicator of competitiveness.

- Comparative Evaluation: Data allows us to compare results between procedures, processes and equipment across time and space. This allows us to identify performance trends and to evaluate and spread best practices. My friend and colleague Hans-Georg Scheibe with ROI* describes this quite well:

“In our projects, “digitally enabled change and performance“ often means to provide the right information to different stakeholders. E.g. to gather data from comparable machines all over the world, and to compare a dedicated machine with the others. There is always a best and a worst and when you ask why, you get a chance to improve. Or to gather best practices from different teams and to provide this knowledge in a manner that somebody else can use to solve problems directly, or faster or better. This requires connectivity to gather the data – to have a kind of intelligence to make information out of the data and then to turn information into knowledge.”

A Process-Centric Approach

Instead of starting with all the data available – both signal and noise – and pushing it into the process, we start by looking at the process itself and ask what minimum information (data) is required for people closest to the work to make the best decisions.

Why is worker inclusion so important? In practice, we’ve found that only the people doing the work can reliably tell you what information is essential to getting the job done right. Thus, engaging in front-end information conditioning is vital to actually reducing lead times, revealing improvement opportunities and paving the way for a better future-state work process.

The Decision Map

As its name implies, a Decision Map emphasizes the idea that faster and better decisions are the precursor of optimal processes. We start with a fairly traditional view so we can see the process flat on the wall – it could be a swim lane map, box and wire, value stream map, etc. Then we identify places where information is required to make decisions and take action. We pose simple enough queries that often prove to be thorny lines of inquiry such as:

| Who makes the decision and is this right? | There can be no room for ambiguity. |

| What information is really necessary? | Less is more. Extraneous information is inventory and inventory has a carrying cost. |

| Is the decision point in the right place in the value stream or could it be moved or consolidated? | When more than one point makes a decision, it’s an opportunity for no decision. |

| What’s the best way to collect and convey the information? | Critical point here. Some information is best collected and conveyed electronically. Some is better suited for human involvement. This must be sorted out deliberately. |

The maps show us different functions and accountabilities. You will find that some of the same data and information will be allocated to more than one location for different purposes. The point here is that these distributions of information are not a push of all information to be sorted out by the users, but rather they are done with a logical intent to provide only the information necessary to make the best decision at any given node.

Conclusions

For faster and better point-of-use decisions, information must be relevant to the user. Because of this we highlight data that is layered according to function and accountability. While daunting in an environment that identifies with “everybody can and perhaps should know everything”, a disciplined “need to know” approach makes whatever information is conveyed seem more valuable to the user because it is concise and actionable – it sorts out the wheat and the chaff is left behind. In the end, Digitization can enable change and performance in remarkable ways. But, the concept works best when we don’t just throw all kinds of data at people and process and hope for the best. Up front evaluation of the process with the people doing the work is the right way to start. It makes change stickier and reduces rework and frustration. Most of all, it gets to optimal performance much, much faster.

==========

Want to know more about how Kaufman Global helps clients manage change and improve performance? Contact us.

*ROI Management Consulting, AG is a German-headquartered, network partner of ours that specializes in operational performance.

Three OpEx Questions and Answers

/in Engagement, Leadership /by Amy HowardA small group recently posed a few questions to us about Operational Excellence, leadership and change. They were looking to get started on their journey and wanted to understand our perspective on some of the critical elements. Here’s a recap of the ensuing discussion with OpEx questions and answers. If you’ve got some questions about OpEx, send us a note (hit the Contact button and start the discussion there). With a dialogue like this, we all learn something.

—

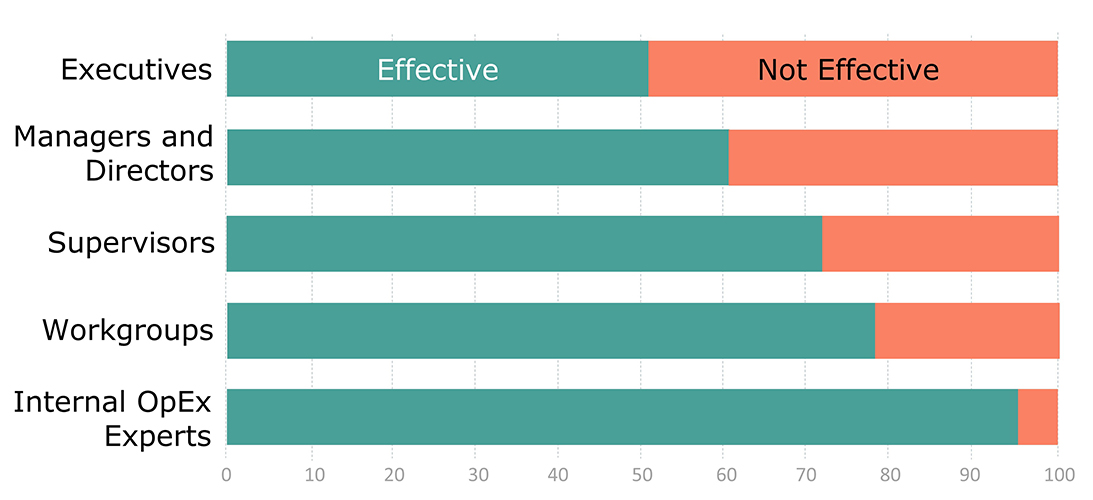

Q. Leaders mostly understand the benefit of engagement and often see OpEx as a way to obtain this, yet it seems that leaders are not well equipped to make this happen. In fact, the training for leaders is often ineffective. How do we overcome this gap?

A. The graph below is sourced from our YE16 OpEx survey report. It shows how the surveyed organizations ranked the effectiveness of training at various levels of the organization and across a variety of business types:

Img 1 – The relative effectiveness of OpEx and Engagement Training at different levels of the organization. It’s notable that training is deemed most effective at the lowest levels of the organization while executive level training is deemed effective only about 50% of the time.

We can all see the connection between better engagement scores and improved performance, however there is a lot of confusion about what good engagement looks like. Often engagement is thought to be more frequent face time between bosses and subordinates, 360 feedback, suggestion programs, and so on. Rather, good engagement is about giving people the ability to directly influence their work. It recognizes basic human needs that include the power to make decisions, the ability to control outcomes and being part of something bigger. These attributes are not naturally occurring in many work environments so equipping leaders to enable OpEx is about training and coaching them on the essential actions and behaviors they must take to engage and align the organization from top to bottom.

Our approach to ensuring effective leadership training starts with the Managers / Executive Lean Overview workshops. These sessions quickly inform the team with a common vocabulary, awareness and understanding of:

- Lean concepts and the Lean enterprise

- Developing the right culture, structure and behaviors to support Lean

- Managing resistance to uncertainty, and

- Driving measurable results linked to the business strategy and objectives

Tools and methods are covered, but gaining expert capability on them is not specifically intended. Rather, this portion of the workshop is meant to provide context for how front line practitioners apply problem-solving tools to achieve desired business outcomes.

Our primary objective with leaders and managers is to provide insights that help them define and develop their own leader standard work. This means doing the hard work of changing some of their own behaviors and habits to be able to actively coach and demonstrate support for Lean to the organization as implementation begins.

Beyond training and workshops, coaching is an important element that we always employ during project work with clients. Coaching is about observing behaviors and suggesting alternatives that can be more effective at delivering certain results. A simple example: If you want people to be more engaged, ask leading questions as opposed to prescribing a potentially ill-conceived solution. In this way, everyone learns something and engagement is supported instead of stifled.

Q. If the leaders are not equipped to lead engagement, can implementation still be successful if delegated to a lower level?

A. No. We’re talking about a shift here that must be valued up and down the organization and especially at the top. These values drive subtle and not so subtle behaviors that become part of the culture and transcend market shifts and personnel changes. Here we assume “implementation” to be a sustainable OpEx system. A leader who is equipped to lead engagement not only understands the benefits, but values the operating norms that better engagement brings.

Since a lot of the heavy lifting and day-to-day activities of implementation are in fact delegated, it’s important to understand how to help leaders do this. We talked about the training and coaching aspect for leaders in Q1 above. In addition to understanding the value of better engagement, the organization must know how to do it.

Everyone in the organization must be expected to spend a small percentage of time on improving the business ― as opposed to running the business. In the simplest terms, this means allowing workers some freedom to fix problems that affect their day-to-day work at the micro-process level. Supervisors and middle managers aren’t exempt: They too should spend about an hour a week addressing slightly more “macro” problems that affect their areas and people. At all levels, the most effective improvement efforts are team-based to drive process ownership and accountability.

Since exactly how to do engagement can be described, the activities can be tracked. This is important because it moves leaders beyond the idea of just “valuing engagement” (because who doesn’t right?) to “knowing how to DO engagement.” Only when this happens can implementation be effectively delegated.

Q. How important are engagement scores to measuring the success of OpEx? What measures would be more important to determining success?

A. Engagement scores are important. OpEx and engagement scores (from surveys and audits) are directly related. Successful Operational Excellence is in large part the result of good engagement. So engagement scores are a good lagging indicator of OpEx and a great leading indicator of operational performance.

A focus on leading indicators is a good place to start. Here’s a way to think about indicators:

- Leading indicators ― Instead of a “result” metric, leading indicators are often the measurable actions that are taken to achieve a result. For engagement these are the structures and mechanisms we use to cause engagement – for example, the Executive Steering Committee (ESC), and Lean Daily Management System®. These structures describe specific, measurable activities that are part of a high-functioning OpEx system.

- Middle indicators are the process performance measures ― and the associated plans to improve ― at the macro and micro-process levels. These are a tangible reflection of the living adoption of OpEx. The organization likes these a lot because they show something is being done to improve results.

- Engagement scores are an important lagging indicator that provides proof and external validation that the OpEx system is working (or not). Those who score the highest go beyond better communication and asking people for more feedback. They incorporate ways for employees to have direct input into the work that they do – that is, the work that is relevant for them.

==========

Want more detail on these topics? You can download the full survey report – An Examination of Operational Excellence – from the Resources section of our website. You’ll need to register.

To learn more about enabling leadership to connect the dots between engagement and value, check out our White Paper: Engage the Organization – And a Performance Culture Will Follow.

Five Reasons for Better Employee Retention

/in Engagement /by Amy HowardThe cost of poor employee retention is significant and ever increasing. The ability to retain good people is a huge competitive advantage. Whether the market is going up or down, turnover is a factor for all employers, no matter what your business.

Not sure retention is an area you really need to spend energy on? Consider this… with strong employee retention strategies and tactics, you:

- Avoid predictable re-staffing costs and gaps

- Guard intellectual property drain

- Preserve customer relationships

- Don’t enable your competitors

- Develop positive buzz about your organization

Those are some pretty critical wins. And, they all contribute to significantly better business performance. So why not do it right? And by right, we don’t just mean pay increases, stock options and / or bonuses. These pieces alone won’t solve your retention issues. It’s not all about the money… really. While financial incentives can buy some time, they do little to build confidence in the culture of the organization and the enterprise. A low retention rate is always a symptom of other issues.

Without a practical employee retention strategy in place, organizations find themselves parting with a higher portion of their best and most qualified talent, the result of which is losses in productivity, time and money. So how do you stop the bleeding? First, focus on the heart of the issue… people.

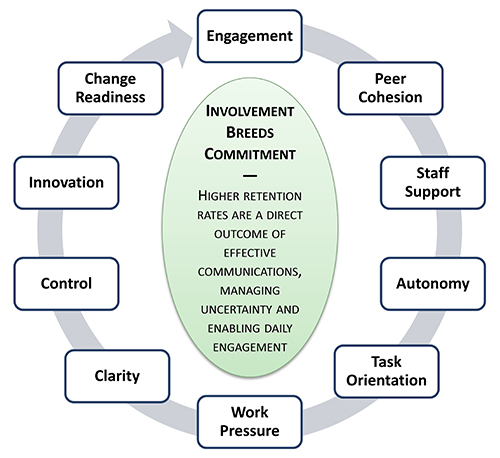

The Most Important Employee Retention Factor is Engagement

This chart shows characteristics that frame highly-retentive workplaces

The number one place where organizations get it wrong is engagement. That’s right, when people leave, it’s most often because they did not feel a sense of accomplishment or belonging. People want to feel like they are part of something. For decades, surveys have concluded that compensation and benefits, while important, always rank lower than belonging and the ability to contribute meaningfully when it comes to job satisfaction. Don’t ignore this!

What to Do

There are plenty of ways to improve retention by getting (and keeping) people engaged. Start by including people in improvement activities like process mapping – those working inside the process always know the most about value and waste where they work – this is their chance to contribute their knowledge! Engaging them in the hands-on work of fixing identified improvements should follow via small focused projects (Kaizen Events and Rapid Improvement Events). To ensure energy and support for these efforts, leaders should receive training and alignment coaching to help them understand that it’s OK to give up some control and let the organization contribute more from the frontlines.

To move beyond a project-based approach to engagement, consider the structure and discipline embodied in Kaufman Global’s Lean Daily Management System®. This is the real deal when it comes to sustainment and a structure that keeps people involved on a day-to-day basis within their workgroups.

Supplemental Reading Recommendation:

Supplemental Reading Recommendation:

White Paper | Engage the Organization and a Performance Culture Will Follow

When an organization is formally and consistently engaged, a culture of performance follows. Understanding how to achieve a performance culture, why it’s so elusive for many leaders and their organizations, and what it takes to make it reliable is the key to sustainable improvement.

An Afternoon Spent Process Mapping is an Afternoon Well Spent

/in Grab Bag /by Kaufman GlobalEarlier this month we spent a few hours with the great team at Jefferson Electric to help them do their first process mapping exercise. They are thinking hard about how to be more effective and standard in the ways they work so that they can continue to grow their business and provide opportunities for new team members to join their organization. We had a great time learning about their solar business and seeing them collaborate as a cross-functional team — really getting to the nitty gritty of how they can better connect their sales and field operations. No team is too small to tackle making positive change — it benefits the internal and external clients and enables agility and responsiveness! #solar #jeffersonelectric #teambuilding #CIisforeveryone

Team discusses identified improvement opportunities and ranks them via use of an Impact Difficulty Matrix

Results Improve When Leaders Give Up Some Control

/in Change Management, Leadership /by Jerry TimpsonTransformation requires a fundamental shift in how the organizations collaborate to make real change happen.

When it comes to guiding an organization through transformative change, control is the determining factor. How much design and direction is pushed down from the top and how much discretion is left to the rest of the organization will make or break any initiative. The best outcomes are achieved by striking the right balance between two approaches: Top-down command and control versus autonomous decision making. Moving the organization off their status quo means certain things must be directed and enforced, yet many organizations fail because so much of their energy is focused on controlling the wrong things.

When it comes to guiding an organization through transformative change, control is the determining factor. How much design and direction is pushed down from the top and how much discretion is left to the rest of the organization will make or break any initiative. The best outcomes are achieved by striking the right balance between two approaches: Top-down command and control versus autonomous decision making. Moving the organization off their status quo means certain things must be directed and enforced, yet many organizations fail because so much of their energy is focused on controlling the wrong things.

Successful transformation efforts demand collaboration up, down and across the enterprise. For process optimization to occur, the organization must establish ways for people doing their work to be continuously involved. Significant changes (processes, procedures, work standards, etc.) must be developed collaboratively. If new methods and approaches for process, communication, safety and efficiency are foisted onto the organization, resistance mounts and the game is over before it’s even started.

True Facts

- Autonomy and recognition are at the top of every single study ever conducted about what motivates people in their work. Without these elements, engagement dies and performance suffers. Self-regulating systems provide these attributes naturally.

- People know more about what is going on in their process or work area than anyone else. It is impossible to optimize any process without direct input and frequent feedback from those doing the work.

- People will not naturally form themselves into a structure of engagement that focuses on process efficiency. Instead, they will form personal networks that minimize conflict. Correcting this tendency is where leadership focus is critical in helping to drive process ownership and improvement through cross-functional teams.

Culture Is No Excuse for Poor Leadership

The culture of the organization and individual leadership styles will impact how transformation efforts go. It’s usually difficult to tease one out from the other since they are the product of their collective and often mutual experiences. Even so, it is a mistake to use culture as an excuse for poor progress. There are ways for leaders to adjust their approach within the context of the existing culture. In top-down environments, unless there are real changes in the fundamentals of collaboration, it soon becomes evident that the “transformed” enterprise looks and operates as it always has.

Control Systems are Easy to Recognize

Self-Regulating Systems – Feedback, input and action at the work-group level are the hallmarks of good performance systems. Self-regulating systems engage the organization to do three things:

- Self-monitor current performance

- Independently generate ideas about how to improve

- Take autonomous actions to improve outcomes

These systems integrate those doing the work in the design of the process and ask what needs to be done to optimize performance. These systems are less bureaucratic and faster to react.

Command and Control Systems – Here, process design and work standards are developed far away from the work processes. Command and control systems:

- Externally monitor, audit and report current performance back to those doing the work

- Mandate what to improve – often focused on systems, not processes

- Authorize actions that are compliant with their control function

Those who embrace and perpetuate authoritative command and control systems believe that top down management knows more about how work should be done than those closest to the work. These “managers” hold power dearly and resist engagement for fear of losing power and control.

Authoritarian organizations are less efficient and less effective than those where a certain and significant control is pushed down into the organization. When this happens, reaction times in the dynamic environment speed up and safety and efficiency improves because decisions can be made faster. Standardizing and enforcing how the organization engages as a self-regulating system yields the greatest long-term benefit. Unfortunately those managers who survive in top-down systems are the usually the last ones willing to give up “their” control.

Loosen Your Grip

Command and control styles dominate because they are more traditional and more familiar. For bosses and managers, giving up control is tough, especially when under stress. Self-regulating systems don’t require any less work, but in them the direction from the top shifts. They require people to own their performance and enforce the best framework to make this happen.

For those control freaks out there who must control something, fear not ― moving into a more autonomous environment requires plenty of leadership and direction. No organization comes together one day and says, “Hey, let’s all take some control and regulate ourselves and own our performance!” Getting to this place requires a transition of power that requires a lot of work for both traditional leaders and their organizations who are used to being told exactly what to do. People are smart though, and they will find the best ways to optimize processes, enable standards and share learnings if they are given the chance and a mandate. Start by describing a structure that accelerates engagement, collaboration and autonomy and then make sure people are fully subscribed.

Lean Daily Management System

/in Engagement /by Jerry TimpsonThe Lean Daily Management System (LDMS): Using Structure to Engage Employees and Optimize Value

In the late 1990s, when Kaufman Global developed the Lean Daily Management System® (LDMS®), we recognized that “Lean” as a method for improving business was often viewed as a set of tools aimed at machines and inventory. On the surface, and in the simplest of explanations, it was considered to be a group of useful techniques that could be “directed and applied”. I think this was more of a Western interpretation that still reverberates today. In this, the practitioners of the day put less emphasis on the human element and treated engagement as a collateral benefit of Lean, rather than the primary contributor to Lean results. Much of the information available focused on technical aspects such as pull systems, inventory leveling and quick change-over with a bias for discrete manufacturing versus continuous flow, business process or service industries.

Consider these highlights from the 1990s Lean landscape:

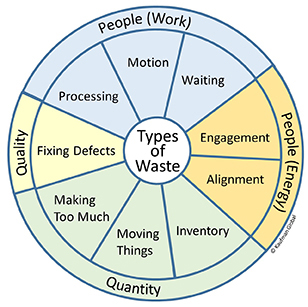

Taiichi Ohno’s original waste wheel updated with People Energy wastes: Engagement and Alignment

- Taiichi Ohno’s seven wastes had not yet been updated to include People Energy Wastes of Alignment and Engagement. This has since been added to present day waste wheel diagrams (right), but it is an addition that Ohno probably would agree with today. He keenly understood the value of engagement and human intellect when he said in his book Workplace Management (Ohno, 1988), “Only the gemba can do cost reduction.”

- The Machine that Changed the World (Womack, Jones, & Roos, 1990). For a decade this book was the primary source of Lean inspiration as manufacturers attempted to emulate Toyota. It is still a compelling description of the benefits of Lean vs. more traditional forms of production. The book describes worker engagement as an important element of the Toyota Production System but it does not peg it as the foundation. Lower inventories and improved product flow are viewed as the causes of higher productivity and better quality when they are actually the effects of a more engaged workforce.

- Learning to See (Rother & Shook, 1998). All about Value Stream Mapping, it is still the preferred source for this technique for understanding waste and value. It is most effective in manufacturing environments where inventory can be converted to time.

Power to the People

Our fundamental belief then and now is that Lean is a people system, not a technical one. Think of Lean tools like Quick Changeover, Error Proofing, Pull Systems, or Kaizen Events as waste elimination shovels. They work great, but they are useless without some keen insight about where to dig. This was the missing link we sought to address as we first described LDMS. It gives natural work teams the ability to make decisions about where to dig based on their understanding of their issues and performance. Combine this insight with the authorization for them to actually take control and utilize some structured problem solving techniques, and you have a self-regulating improvement engine.

The Lean Daily Management System Methodology

It’s about workgroup engagement:

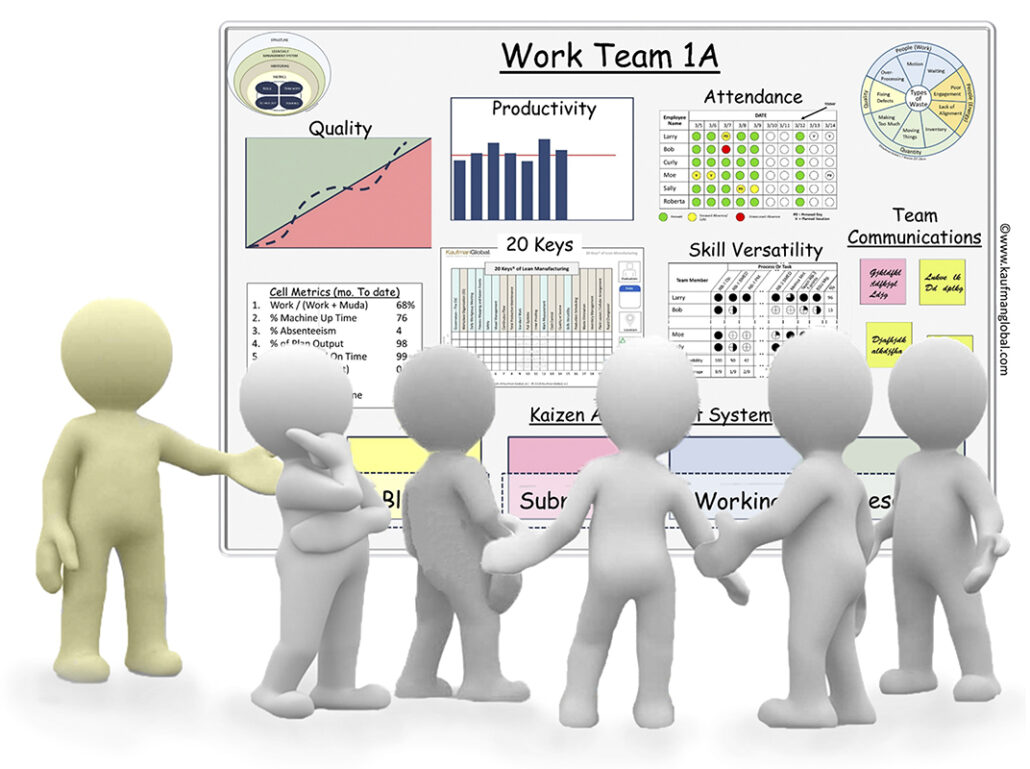

The Lean Daily Management System – Shift Start-Up meeting at a Primary Visual Display board.

The Lean Daily Management System is done by intact workgroups with common tasks and deliverables. They perform the standard procedures that help teams continuously improve their day-to-day work (Kaizen). Vital components of the Lean Daily Management System:

- A daily shift start-up meeting (SSU) (no more than 10 minutes) at the

- Primary Visual Display (PVD) board

- Kaizen Action Sheet (KAS) improvement system

- The 20-Keys® for assessment, planning and action

- Daily short interval coaching (SIC) by supervisors

The Lean Daily Management System is the primary means of engaging the broader organization. It is the manifestation of work group participation and this engagement is the fastest route to the overall objective of Lean which is to maximize customer value by minimizing waste. Or said another way: Deliver at each step what you need, when you need it, at ever-increasing levels of quality and customer satisfaction. While this cannot be achieved via top-down control, leadership does have an important part to play. “Doing” LDMS must be supported, expected, encouraged and required from above, otherwise it won’t happen consistently enough, broadly enough or often enough to become the way the organization does business.

LDMS Behaviors and Actions are Specific and Observable

The constructs of LDMS are specific. They describe activities and behaviors that are observable. This gives leadership a natural and specific way to interact with and support the teams. For example, one could ask: “Do you have good teamwork? Are you communicating? Do you measure your work and performance?” In an LDMS environment, all of these things are observable and the teams are able to speak directly to how they do it. That empowerment drives accountability and process ownership downward, where it belongs.

The constructs of LDMS are specific. They describe activities and behaviors that are observable. This gives leadership a natural and specific way to interact with and support the teams. For example, one could ask: “Do you have good teamwork? Are you communicating? Do you measure your work and performance?” In an LDMS environment, all of these things are observable and the teams are able to speak directly to how they do it. That empowerment drives accountability and process ownership downward, where it belongs.

The Lean Daily Management System gives organizations outside the realm of manufacturing something to grasp. When you think of Lean as waste elimination and LDMS as the standard work of an engaged organization, it opens a world of possibilities that go beyond the shop floor. In our experience, LDMS works everywhere. Contents are adjusted – metrics for example will be different in functional and administrative environments than in manufacturing. But when people actively participate in improving the work that they control, they always find ways to innovate and adjust appropriately.

Where is it working? Here are a few examples:

- Industry: Goodrich, AGCO, Becton Dickinson, Johnson and Johnson, Genentech, Haldex, IR, Goodyear, Owens Corning, Nabors

- Healthcare: Sutter Healthcare Systems, Oregon State Hospital, Mississippi State Hospital, Lincoln Healthcare Network

- Government: State of Oregon, State of Indiana, State of Delaware, UK Highways Agency

Why The Lean Daily Management System Works

Should you do it?.. Of course! LDMS makes Lean sticky.

- People have more personal control and ownership of the work that they do. Individual and team accomplishments become visible.

- Performance issues and opportunities are more transparent.

- Process changes and improvement efforts are better connected to day-to-day activities and standard work is easier to achieve.

- LDMS engages minds and hearts and provides a vessel for employees to contribute in ways that are meaningful and rewarding to them.

Even with all these positives, be prepared for some resistance. It’s something new and people will have lots of questions as the system is coached into the organization. Leaders needs to be encouraged to stay the course until the culture starts to recognize that a broad and proactive approach to performance improvement is the best way to eliminate waste and improve customer value.

********************

Kaufman Global began teaching and implementing the Lean Daily Management System in 1999. It was first described and published in our groundbreaking White Paper: WIn-Lean® Manufacturing in 2000.

In 2017 we updated our content to include even greater emphasis on the fact that the waste of People Energy (Engagement and Alignment) is still the greatest opportunity for any organization seeking to improve performance. For a full description of how and why LDMS fits into any Lean system, download a copy of our White Paper: Implementing Lean Manufacturing: A Holistic Approach.

Results from Kaufman Global clients who have implemented and are using the LDMS:

Oregon State Hospital uses the Lean Daily Management System and here: Oregon State Hospital Presentation

BD uses LDMS everywhere: BDs Corporate Citizenship Report – see page 36

Tier 1 automotive company that deployed the Lean Daily Management System globally

Pharmaceutical company uses LDMS as a cornerstone of enterprise Lean implementation

********************

References

Ohno, T. (1988). Workplace Management. Cambridge, MA: Productivity Press.

Womack, J., Jones, D., Roos, D. (1990). The Machine That Changed The World. Based on the Massachusetts Institute of Technology 5-million dollar 5-year study on the future of the automobile. New York, NY: Rawson Associates.

Rother, M., Shook, J. (1998). Learning To See: Value Stream Mapping to Create Value and Eliminate Muda.

Lareau, E. W. (2000) White Paper:WIn-Lean® Manufacturing.