Three OpEx Questions and Answers

A small group recently posed a few questions to us about Operational Excellence, leadership and change. They were looking to get started on their journey and wanted to understand our perspective on some of the critical elements. Here’s a recap of the ensuing discussion with OpEx questions and answers. If you’ve got some questions about OpEx, send us a note (hit the Contact button and start the discussion there). With a dialogue like this, we all learn something.

—

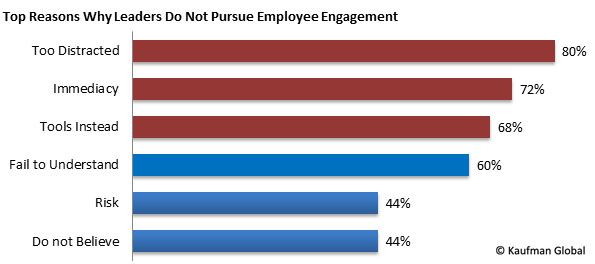

Q. Leaders mostly understand the benefit of engagement and often see OpEx as a way to obtain this, yet it seems that leaders are not well equipped to make this happen. In fact, the training for leaders is often ineffective. How do we overcome this gap?

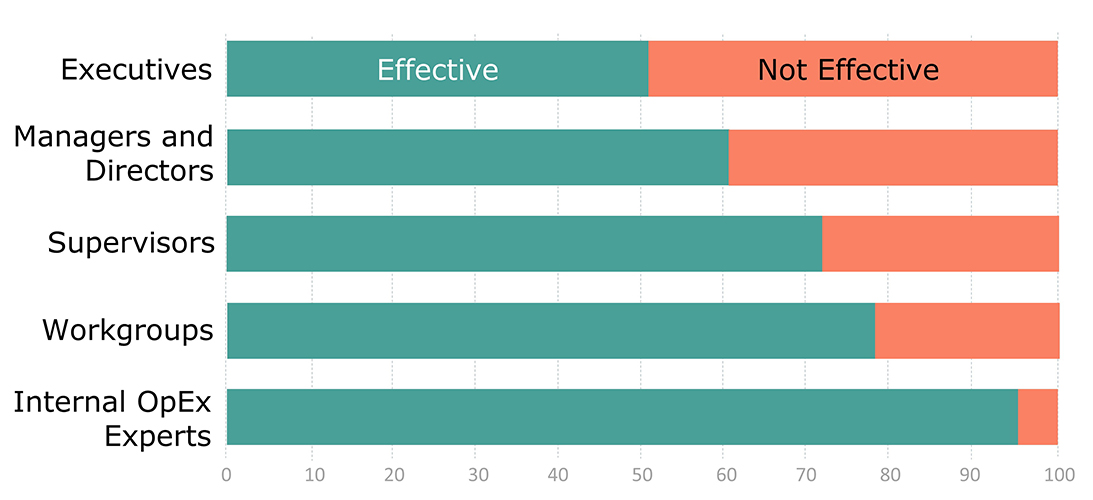

A. The graph below is sourced from our YE16 OpEx survey report. It shows how the surveyed organizations ranked the effectiveness of training at various levels of the organization and across a variety of business types:

Img 1 – The relative effectiveness of OpEx and Engagement Training at different levels of the organization. It’s notable that training is deemed most effective at the lowest levels of the organization while executive level training is deemed effective only about 50% of the time.

We can all see the connection between better engagement scores and improved performance, however there is a lot of confusion about what good engagement looks like. Often engagement is thought to be more frequent face time between bosses and subordinates, 360 feedback, suggestion programs, and so on. Rather, good engagement is about giving people the ability to directly influence their work. It recognizes basic human needs that include the power to make decisions, the ability to control outcomes and being part of something bigger. These attributes are not naturally occurring in many work environments so equipping leaders to enable OpEx is about training and coaching them on the essential actions and behaviors they must take to engage and align the organization from top to bottom.

Our approach to ensuring effective leadership training starts with the Managers / Executive Lean Overview workshops. These sessions quickly inform the team with a common vocabulary, awareness and understanding of:

- Lean concepts and the Lean enterprise

- Developing the right culture, structure and behaviors to support Lean

- Managing resistance to uncertainty, and

- Driving measurable results linked to the business strategy and objectives

Tools and methods are covered, but gaining expert capability on them is not specifically intended. Rather, this portion of the workshop is meant to provide context for how front line practitioners apply problem-solving tools to achieve desired business outcomes.

Our primary objective with leaders and managers is to provide insights that help them define and develop their own leader standard work. This means doing the hard work of changing some of their own behaviors and habits to be able to actively coach and demonstrate support for Lean to the organization as implementation begins.

Beyond training and workshops, coaching is an important element that we always employ during project work with clients. Coaching is about observing behaviors and suggesting alternatives that can be more effective at delivering certain results. A simple example: If you want people to be more engaged, ask leading questions as opposed to prescribing a potentially ill-conceived solution. In this way, everyone learns something and engagement is supported instead of stifled.

Q. If the leaders are not equipped to lead engagement, can implementation still be successful if delegated to a lower level?

A. No. We’re talking about a shift here that must be valued up and down the organization and especially at the top. These values drive subtle and not so subtle behaviors that become part of the culture and transcend market shifts and personnel changes. Here we assume “implementation” to be a sustainable OpEx system. A leader who is equipped to lead engagement not only understands the benefits, but values the operating norms that better engagement brings.

Since a lot of the heavy lifting and day-to-day activities of implementation are in fact delegated, it’s important to understand how to help leaders do this. We talked about the training and coaching aspect for leaders in Q1 above. In addition to understanding the value of better engagement, the organization must know how to do it.

Everyone in the organization must be expected to spend a small percentage of time on improving the business ― as opposed to running the business. In the simplest terms, this means allowing workers some freedom to fix problems that affect their day-to-day work at the micro-process level. Supervisors and middle managers aren’t exempt: They too should spend about an hour a week addressing slightly more “macro” problems that affect their areas and people. At all levels, the most effective improvement efforts are team-based to drive process ownership and accountability.

Since exactly how to do engagement can be described, the activities can be tracked. This is important because it moves leaders beyond the idea of just “valuing engagement” (because who doesn’t right?) to “knowing how to DO engagement.” Only when this happens can implementation be effectively delegated.

Q. How important are engagement scores to measuring the success of OpEx? What measures would be more important to determining success?

A. Engagement scores are important. OpEx and engagement scores (from surveys and audits) are directly related. Successful Operational Excellence is in large part the result of good engagement. So engagement scores are a good lagging indicator of OpEx and a great leading indicator of operational performance.

A focus on leading indicators is a good place to start. Here’s a way to think about indicators:

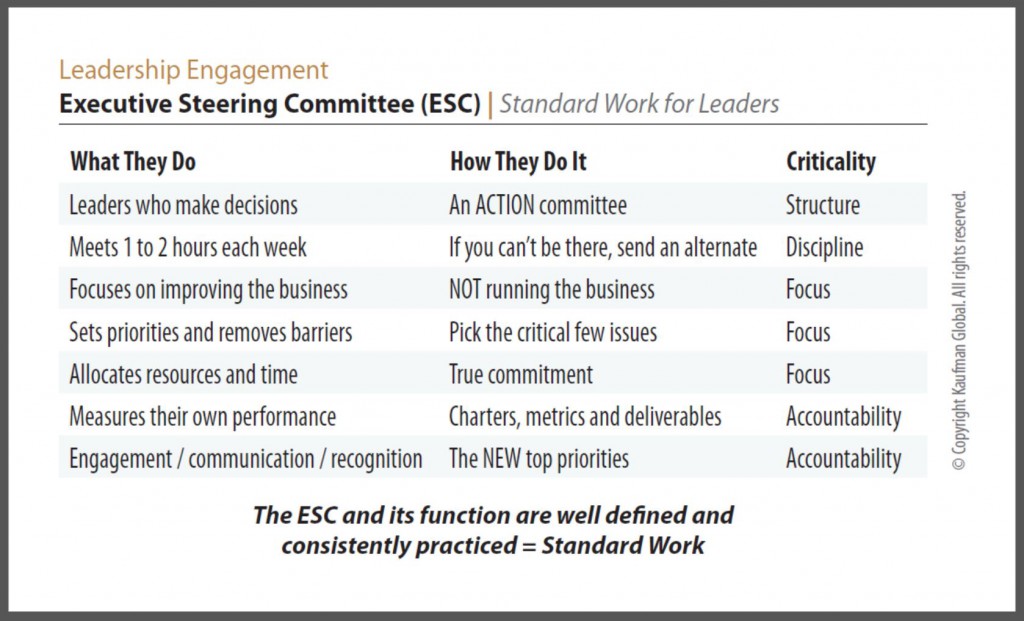

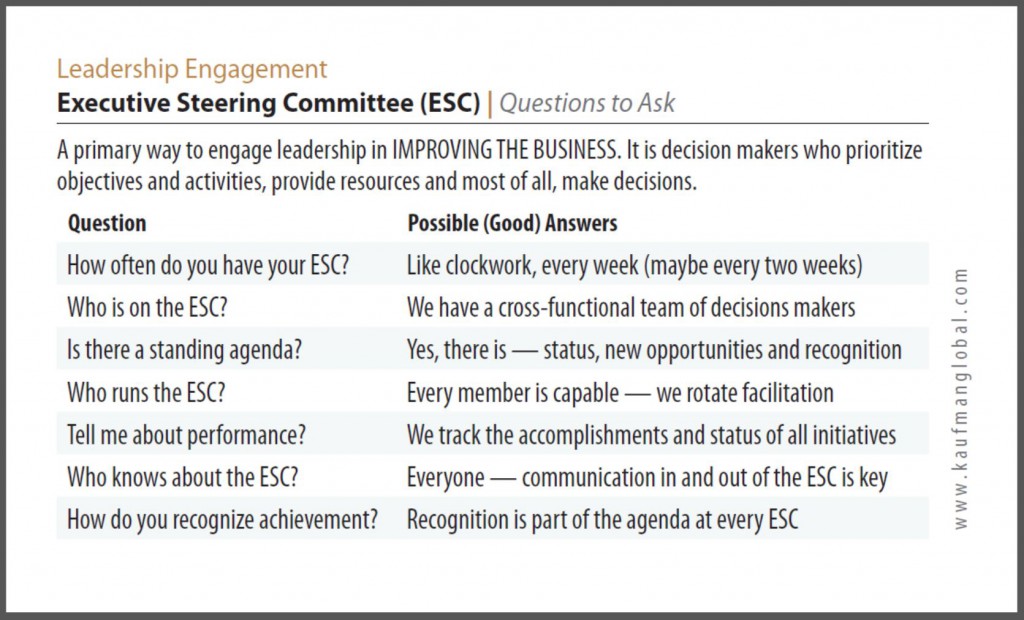

- Leading indicators ― Instead of a “result” metric, leading indicators are often the measurable actions that are taken to achieve a result. For engagement these are the structures and mechanisms we use to cause engagement – for example, the Executive Steering Committee (ESC), and Lean Daily Management System®. These structures describe specific, measurable activities that are part of a high-functioning OpEx system.

- Middle indicators are the process performance measures ― and the associated plans to improve ― at the macro and micro-process levels. These are a tangible reflection of the living adoption of OpEx. The organization likes these a lot because they show something is being done to improve results.

- Engagement scores are an important lagging indicator that provides proof and external validation that the OpEx system is working (or not). Those who score the highest go beyond better communication and asking people for more feedback. They incorporate ways for employees to have direct input into the work that they do – that is, the work that is relevant for them.

==========

Want more detail on these topics? You can download the full survey report – An Examination of Operational Excellence – from the Resources section of our website. You’ll need to register.

To learn more about enabling leadership to connect the dots between engagement and value, check out our White Paper: Engage the Organization – And a Performance Culture Will Follow.

When it comes to guiding an organization through transformative change, control is the determining factor. How much design and direction is pushed down from the top and how much discretion is left to the rest of the organization will make or break any initiative. The best outcomes are achieved by striking the right balance between two approaches: Top-down command and control versus autonomous decision making. Moving the organization off their status quo means certain things must be directed and enforced, yet many organizations fail because so much of their energy is focused on controlling the wrong things.

When it comes to guiding an organization through transformative change, control is the determining factor. How much design and direction is pushed down from the top and how much discretion is left to the rest of the organization will make or break any initiative. The best outcomes are achieved by striking the right balance between two approaches: Top-down command and control versus autonomous decision making. Moving the organization off their status quo means certain things must be directed and enforced, yet many organizations fail because so much of their energy is focused on controlling the wrong things. Clients never say: “We want to transform and do better, but we don’t care if we sustain the improvements.” Clients always profess a sincere desire to sustain results. This intent is so pervasive that during the past 20 years we’ve seen the rise of Operational Excellence as a legitimate function across wide swaths of business and industry. Yet most organizations fail to realize this apparently lofty goal. Low levels of lasting success are usually explained at a tactical level, but the reasons that leaders and their organizations get it wrong goes much deeper.

Clients never say: “We want to transform and do better, but we don’t care if we sustain the improvements.” Clients always profess a sincere desire to sustain results. This intent is so pervasive that during the past 20 years we’ve seen the rise of Operational Excellence as a legitimate function across wide swaths of business and industry. Yet most organizations fail to realize this apparently lofty goal. Low levels of lasting success are usually explained at a tactical level, but the reasons that leaders and their organizations get it wrong goes much deeper.

topic. If you doubt this, read a little about prospect theory, loss aversion and anchoring. Here, we are talking about the benefits that are derived from efficient and effective processes.

topic. If you doubt this, read a little about prospect theory, loss aversion and anchoring. Here, we are talking about the benefits that are derived from efficient and effective processes. Upon doing some research, there were no ground-breaking “bacon discoveries” to be found. However, I did learn about some healthier ways to prepare and eat it. Reading the countless available articles, I had a sudden epiphany. It hit me that the meticulous handling of bacon provides a valuable lesson. There’s a right and wrong way to do things, and, in many cases, the right way is neither the easier nor the faster path (but it’s still “the

Upon doing some research, there were no ground-breaking “bacon discoveries” to be found. However, I did learn about some healthier ways to prepare and eat it. Reading the countless available articles, I had a sudden epiphany. It hit me that the meticulous handling of bacon provides a valuable lesson. There’s a right and wrong way to do things, and, in many cases, the right way is neither the easier nor the faster path (but it’s still “the