Secure a high-performance organizational culture with the Lean Daily Management System

By Sean Wright

LDMS is the way to create an organization of engaged problem-solvers who lift results every day.

No matter your geography or organization size, LDMS® (Lean Daily Management System®) is the path to securing a performance culture where problem-solving, employee involvement and leadership engagement become the norm. In this six-post series we begin by describing what LDMS is. In subsequent posts we’ll describe in detail the various components of the system, why it works and what you get with it.

What is LDMS?

Our fundamental belief is that Lean is a people system and with minor care can be largely self-managed.

Background: Kaufman Global created LDMS in the 90s to address the gap we perceived between practically applying waste elimination tools and connecting people and their work to enterprise imperatives. Much like a computer has an operating system to manage communications, security, resources, error detection, filing and such, we consistently noticed a lack of that sort of thinking applied within most workgroups. Similarly, we thought that a “workgroup operating system” would serve to effectively enable communications, control resources, redirect for errors, identify and record only important data and generally help to obtain predictable outcomes. While people are not computers, the workgroups they compose appeared similarly less productive than they otherwise could be without some operating system and structure in place. So, with these notions we framed LDMS. In so doing, we also incorporated the overarching objective of Lean — maximizing customer value by minimizing waste — by enabling those on the front line to better detect issues, manage responses, and ultimately improve results every day.

Background: Kaufman Global created LDMS in the 90s to address the gap we perceived between practically applying waste elimination tools and connecting people and their work to enterprise imperatives. Much like a computer has an operating system to manage communications, security, resources, error detection, filing and such, we consistently noticed a lack of that sort of thinking applied within most workgroups. Similarly, we thought that a “workgroup operating system” would serve to effectively enable communications, control resources, redirect for errors, identify and record only important data and generally help to obtain predictable outcomes. While people are not computers, the workgroups they compose appeared similarly less productive than they otherwise could be without some operating system and structure in place. So, with these notions we framed LDMS. In so doing, we also incorporated the overarching objective of Lean — maximizing customer value by minimizing waste — by enabling those on the front line to better detect issues, manage responses, and ultimately improve results every day.

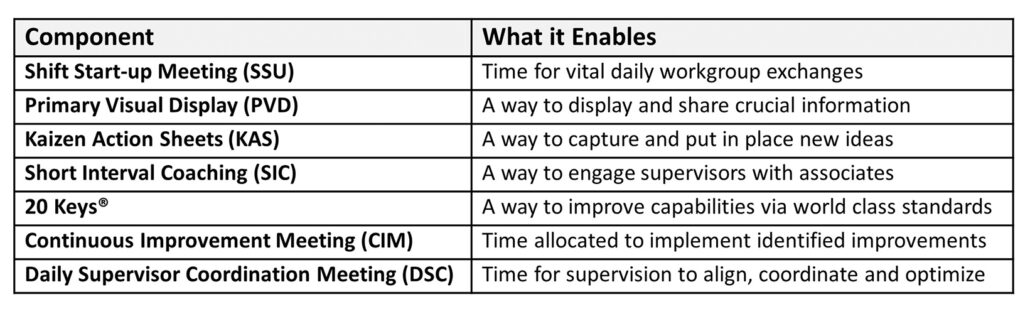

Description: The Lean Daily Management System then became, and remains today, a set of standard procedures that provides the structure (see figure above) and focus for intact workgroups (adjacent or virtual) with common tasks and deliverables to continuously improve their day-to-day work. LDMS workgroups observe performance metrics that they can influence and control themselves. It is intended to engage everyone, tap into their improvement ideas, and in the end… make Lean “sticky”. LDMS is compiled from specific, finite components with a purpose, rationale and context to one another. These components are:

Implemented, LDMS compels observable (and therefore measurable) activities and behaviors serving to drive practical accountability and process ownership to the front lines of the actual work. Our clients often remark that LDMS has been the critical success factor to achieve and sustain results using their own enterprise-wide operational excellence approach!

Getting Started

After leadership decides to integrate LDMS into operational and functional workgroups, preparing to launch your LDMS implementation requires just two things:

1. Prepare informed leaders who can and will support and coach a successful LDMS rollout:

- This is gained through a one to two-day workshop, the Manager’s Lean Overview, held with the designated leadership population. In that, we impart what participants initially expect, an ample deep dive into the topic of applied Lean tools and techniques of which they should be aware. Equally important (actually more so) is the topic of management’s vital role to lead change and manage uncertainty about change. We invest time in describing when, where, how and how often to engage with people to ensure their LDMS journey is a success.

2. Determining the implementation sequence of intact LDMS workgroups by name and location.

- Ideally, this means identifying and accounting for all people in all workgroups, determining which are intact-adjacent and which are intact-virtual. Then, planning the rollout sequence, and preparing and resourcing facilitation to make certain that the workgroups get what they need to successfully integrate what they’ve learned into the daily deliverables with visible performance results.

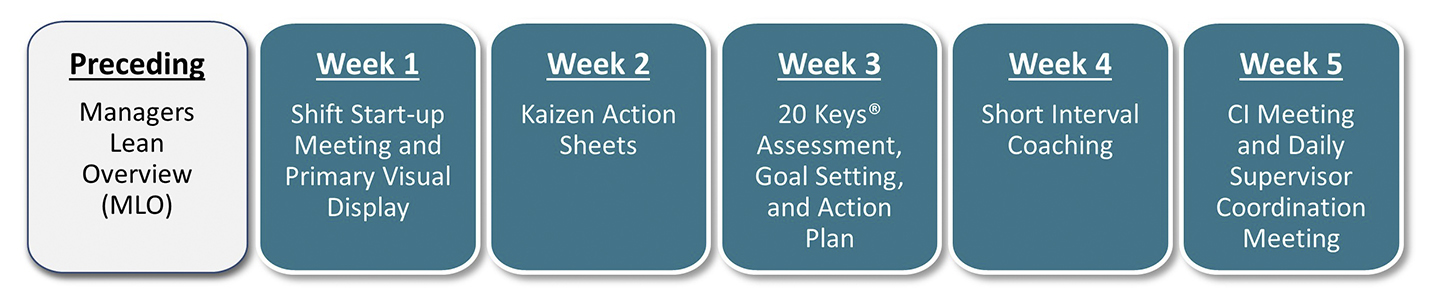

Our five-week implementation sequence that follows (inset below) manageably rolls out LDMS components. It can be for one workgroup or scaled to many in parallel where we coach, teach and demonstrate best practice to ensure a solid foundation is in place achieve rapid performance gains.

Next Time

In Part 2, we’ll cover the Shift Start-up Meeting and Primary Visual Display. In the meantime, if you’d like to start your LDMS teams off right – or, if you’ve already started and you aren’t getting the expected results, we can help. Kaufman Global offer deep, real-world experience, world-class coaching and training at all levels, a rich array of intellectual property, learning materials, and Train-the-Trainer programs all focused on solving actual performance problems, ensuring you get a business result while creating organization capability.