5 Critical Success Factors for Evaluating Operational Performance

Rapid Performance Evaluation

In this post, we outline 5 critical success factors for evaluating operational performance. This is an approach we’ve developed over years of working with clients who want a solid portfolio of improvement projects that are connected to metrics important to the organization.

—

“Ready, fire, aim.”

“If you don’t know where you’re going, any road will get you there.”

“Shoot from the hip.”

These are not sayings you want to hear when you’re trying to set direction and plan for operational improvements. Yet, with poor planning, this is often how situations are described in hindsight. Even if deeper analysis is required, an efficient and effective gap assessment is an invaluable first step.

The best results come when you engage the organization from the start and use comparative benchmarks. The five elements described here, enable open discussion about operations and performance and are the starting point for an effective plan.

A good evaluation process has certain attributes. It:

- Leverages internal experts and external viewpoints

- Incorporates operational realities of the front line along with leadership priorities and,

- Gives everyone a way to make an objective assessment of the gap between the environment that exists and a standard definition of “what good looks like.”

At a site or value stream level, when done well, reliable results can be achieved within a few days.

5 Critical Success Factors for Evaluating Operational Performance

- Confirm the top-level performance metrics for the location being evaluated

- Use a template that provides performance level descriptions for key elements of the operation

- Engage the organization from the start

- Combine objective ratings with subjective views (interviews)

- Prioritize opportunities and describe an implementation approach

1. Confirm the top-level performance metrics

For any operation there are 10 or so metrics that tell the story. For example: inventory, quality, productivity, turnover (people), etc. Vast amount of data does not always translate into usable information. Identify and confirm the critical few operational metrics and then use them as a guide for where to look more closely during the evaluation. This becomes the baseline. From it, progress will be obvious as improvements are made. Later on, more information and more analysis may be required, but for your initial look, keep it simple.

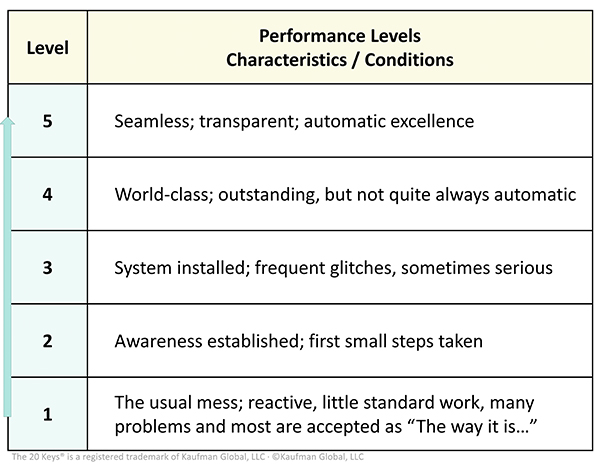

2. Use a Template

The best way to understand the gap is to use a template that describes different levels of performance for various functions. The level descriptions are based on an intuitive general definition of performance at each level. Shown here:

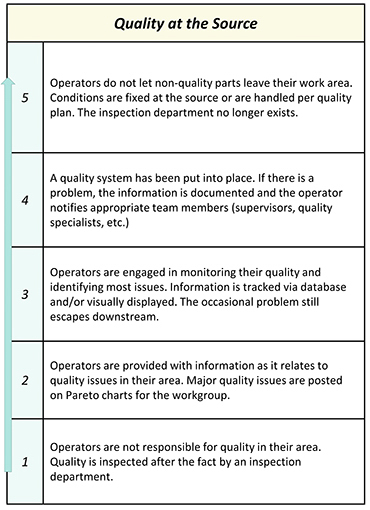

From this foundation, more detailed descriptions can be built for multiple areas of concern. We typically apply 20 Keys for such an evaluation. An Key example (quality) is shown here.

For more examples in several industries and functional areas, go here: Performance Key Examples for manufacturing, oilfield and mining, supply chain.

3. Engage the Organization from the Start

Those working inside the process – at the Gemba, know the most about what is really going on so get them involved from the start. They use the template that describes performance levels as a guide for rating each element. The results show areas of opportunity.

At the same time, the leadership team and functional heads understand areas of concern for the top-level metrics. By interviewing these individuals, patterns emerge. The strengths and opportunities across the organization start to become apparent.

By engaging the organization broadly, everyone owns the answer and the plan. You get better inputs and ensure greater success when it comes to implementing changes in the name of better operational performance.

4. Combine objective ratings with subjective views

A rating system gives the organization a way to establish a baseline, clarify gaps and then measure success. As improvements proceed, better ratings show tangible evidence of the gaps closing. We use a series of three assessment tools that provide different ratings:

- Interviews – These subjective opinions matter. With a standard set of questions, priorities emerge. And we can identify alignment issues that need to be reconciled.

- Vital Systems – Using the same 1-5 rating system levels noted above, we evaluate 10 vital systems including: customer focus, supply chain, engagement, etc. Relevant vital systems vary according to industry type. Each system is described in a way that identifies its critical elements. Vital systems evaluation provides a big-picture view of the operation.

- 20 Keys® – The 20 Keys does a drill-down into the details. They provide guidance on specific improvement activities and exactly what must be done to get to the next level of performance.

5. Prioritize Opportunities and Describe an Implementation Approach

Once the evaluation is complete and the gaps described, the question becomes, “What next?” This question must be answered at least at a high-level. An evaluation that takes less than a week won’t yield a detailed implementation plan and business case, but it will answer questions such as: top operational priorities, engagement issues, leadership alignment and recommended next steps.

Internal and External Views

The internal team knows the most about what is really happening inside the operation. However, even with a good template that has standard definitions, they still have a subjective view. A level of objectivity and broad experience can be extremely beneficial. This usually comes from the outside. A good evaluation balances these two views and enables collaboration between them.

Conclusion

When done well, an evaluation of operational performance is a fantastic starting point for real change and improvement. Follow the 5 success factors described here and you’ll be miles ahead in your efforts.

====

Kaufman Global conducts Rapid Performance Evaluations for clients everywhere. Contact us to learn more about this powerful, inclusive, template-designed method for reading your operations fast.

Learn more about how we think about the topic of Analysis as it relates to our service offerings, click here.

Or, see our post on analyzing extended value streams: Making the Case for Analysis.

Over the past few years, we’ve observed that clients want answers faster than ever before. And while it could be that “time is money,” it seems to us that it’s more related to the frenetic pace of, well, everything these days. Headlines and “apps” often don’t dig deep enough and the “Ready, Fire, Aim” approach has great potential for missteps.

Over the past few years, we’ve observed that clients want answers faster than ever before. And while it could be that “time is money,” it seems to us that it’s more related to the frenetic pace of, well, everything these days. Headlines and “apps” often don’t dig deep enough and the “Ready, Fire, Aim” approach has great potential for missteps.