Posts

Three OpEx Questions and Answers

/in Engagement, Leadership /by Amy HowardA small group recently posed a few questions to us about Operational Excellence, leadership and change. They were looking to get started on their journey and wanted to understand our perspective on some of the critical elements. Here’s a recap of the ensuing discussion with OpEx questions and answers. If you’ve got some questions about OpEx, send us a note (hit the Contact button and start the discussion there). With a dialogue like this, we all learn something.

—

Q. Leaders mostly understand the benefit of engagement and often see OpEx as a way to obtain this, yet it seems that leaders are not well equipped to make this happen. In fact, the training for leaders is often ineffective. How do we overcome this gap?

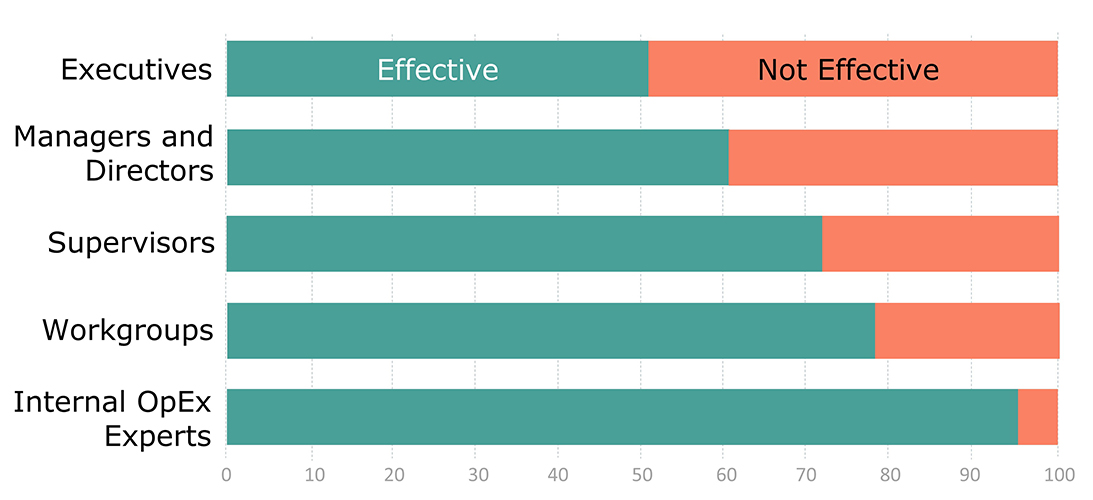

A. The graph below is sourced from our YE16 OpEx survey report. It shows how the surveyed organizations ranked the effectiveness of training at various levels of the organization and across a variety of business types:

Img 1 – The relative effectiveness of OpEx and Engagement Training at different levels of the organization. It’s notable that training is deemed most effective at the lowest levels of the organization while executive level training is deemed effective only about 50% of the time.

We can all see the connection between better engagement scores and improved performance, however there is a lot of confusion about what good engagement looks like. Often engagement is thought to be more frequent face time between bosses and subordinates, 360 feedback, suggestion programs, and so on. Rather, good engagement is about giving people the ability to directly influence their work. It recognizes basic human needs that include the power to make decisions, the ability to control outcomes and being part of something bigger. These attributes are not naturally occurring in many work environments so equipping leaders to enable OpEx is about training and coaching them on the essential actions and behaviors they must take to engage and align the organization from top to bottom.

Our approach to ensuring effective leadership training starts with the Managers / Executive Lean Overview workshops. These sessions quickly inform the team with a common vocabulary, awareness and understanding of:

- Lean concepts and the Lean enterprise

- Developing the right culture, structure and behaviors to support Lean

- Managing resistance to uncertainty, and

- Driving measurable results linked to the business strategy and objectives

Tools and methods are covered, but gaining expert capability on them is not specifically intended. Rather, this portion of the workshop is meant to provide context for how front line practitioners apply problem-solving tools to achieve desired business outcomes.

Our primary objective with leaders and managers is to provide insights that help them define and develop their own leader standard work. This means doing the hard work of changing some of their own behaviors and habits to be able to actively coach and demonstrate support for Lean to the organization as implementation begins.

Beyond training and workshops, coaching is an important element that we always employ during project work with clients. Coaching is about observing behaviors and suggesting alternatives that can be more effective at delivering certain results. A simple example: If you want people to be more engaged, ask leading questions as opposed to prescribing a potentially ill-conceived solution. In this way, everyone learns something and engagement is supported instead of stifled.

Q. If the leaders are not equipped to lead engagement, can implementation still be successful if delegated to a lower level?

A. No. We’re talking about a shift here that must be valued up and down the organization and especially at the top. These values drive subtle and not so subtle behaviors that become part of the culture and transcend market shifts and personnel changes. Here we assume “implementation” to be a sustainable OpEx system. A leader who is equipped to lead engagement not only understands the benefits, but values the operating norms that better engagement brings.

Since a lot of the heavy lifting and day-to-day activities of implementation are in fact delegated, it’s important to understand how to help leaders do this. We talked about the training and coaching aspect for leaders in Q1 above. In addition to understanding the value of better engagement, the organization must know how to do it.

Everyone in the organization must be expected to spend a small percentage of time on improving the business ― as opposed to running the business. In the simplest terms, this means allowing workers some freedom to fix problems that affect their day-to-day work at the micro-process level. Supervisors and middle managers aren’t exempt: They too should spend about an hour a week addressing slightly more “macro” problems that affect their areas and people. At all levels, the most effective improvement efforts are team-based to drive process ownership and accountability.

Since exactly how to do engagement can be described, the activities can be tracked. This is important because it moves leaders beyond the idea of just “valuing engagement” (because who doesn’t right?) to “knowing how to DO engagement.” Only when this happens can implementation be effectively delegated.

Q. How important are engagement scores to measuring the success of OpEx? What measures would be more important to determining success?

A. Engagement scores are important. OpEx and engagement scores (from surveys and audits) are directly related. Successful Operational Excellence is in large part the result of good engagement. So engagement scores are a good lagging indicator of OpEx and a great leading indicator of operational performance.

A focus on leading indicators is a good place to start. Here’s a way to think about indicators:

- Leading indicators ― Instead of a “result” metric, leading indicators are often the measurable actions that are taken to achieve a result. For engagement these are the structures and mechanisms we use to cause engagement – for example, the Executive Steering Committee (ESC), and Lean Daily Management System®. These structures describe specific, measurable activities that are part of a high-functioning OpEx system.

- Middle indicators are the process performance measures ― and the associated plans to improve ― at the macro and micro-process levels. These are a tangible reflection of the living adoption of OpEx. The organization likes these a lot because they show something is being done to improve results.

- Engagement scores are an important lagging indicator that provides proof and external validation that the OpEx system is working (or not). Those who score the highest go beyond better communication and asking people for more feedback. They incorporate ways for employees to have direct input into the work that they do – that is, the work that is relevant for them.

==========

Want more detail on these topics? You can download the full survey report – An Examination of Operational Excellence – from the Resources section of our website. You’ll need to register.

To learn more about enabling leadership to connect the dots between engagement and value, check out our White Paper: Engage the Organization – And a Performance Culture Will Follow.

Sustaining Operational Excellence

/in Uncategorized /by Jerry TimpsonSustaining Operational Excellence: This is an excerpt from the Kaufman Global survey report. For the full report, follow the link at the bottom of this page.

We conducted a survey about sustaining operational excellence. For the survey, we contacted over 100 executives in our network who have deep experience leading operations and operational excellence efforts. Our goal was to examine how organizations are evolving in their construction, use of and thinking about OpEx today. 16 key topics were covered, with Sustainability being one of them. For this section, we wanted to find out how many of the respondents had experienced OpEx build-up and tear-down and, we wanted to learn something about why.

Q: How many times in your career have you seen OpEx efforts built up to a significant level, and then be killed off by the organization (that is, resources retracted, timing deferred, “overhead” cut, unit leaders subvert or ignore it, etc.)?

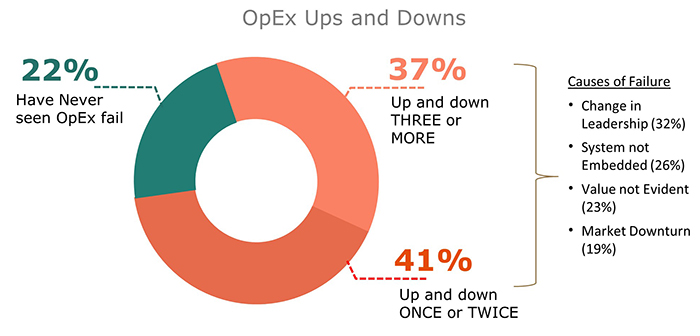

THE DATA: 78% of the population surveyed have seen OpEx fail at least once and a staggering 37% at least three times in their career.

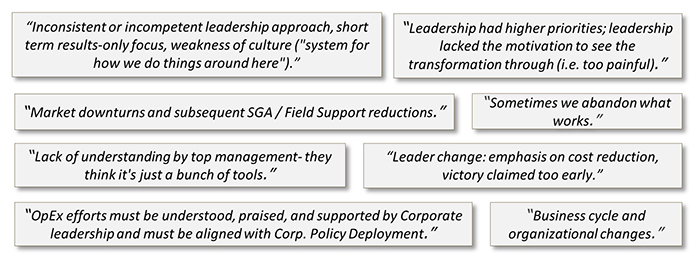

KG POV: The data gives us an indication of how often OpEx fails. The answer is… a lot. It’s easy for organizations to get distracted. For those of you who have not experienced an OpEx failure, consider yourselves lucky. For those of you who have, you’ll appreciate the consistency of participant comments (subset below) from multiple enterprise types about the reasons why.

In looking at all the comments submitted around this question, four themes emerged as reasons for failure (see list to right of the pie chart). They are: Change in Leadership, System not Embedded, Value not Evident (Relevance) and Market Downturn. It’s interesting to note the fairly even distribution of reasons by category. When you pair that with the high rates of failure overall, it tells us that if the system is weak, almost anything can kill it.

If you would like to receive a copy of the full report that includes all 16 topic areas, register and download here: An Examination of Operational Excellence

Operational Excellence Can Save Millions (and Millions)

/in Uncategorized /by Kaufman GlobalWell… the exact number is not certain, but your organizations could get much more from their OpEx by shifting perspective.

Operational excellence is another way of saying “comprehensive process improvement.”

As an enterprise function it’s better than ever. Across business and industry (government, healthcare, services and manufacturing) it delivers year-over-year benefits. Yet, results could be much better. Many of the Operational Excellence (OpEx) programs we encounter are too narrowly defined and treat OpEx simply as deployed resources with some useful tools.

A broader definition recognizes operational excellence as a result and OpEx as a system that affects the entire enterprise. It’s not an overlay, but rather a cohesive network of people applying standard techniques to deliver and improve results.

The Operational Excellence Function Emerges

In the mid-90s, OpEx programs began to emerge from their automotive heritage, branching into other settings where they were perceived to offer a return on investment. Many of those efforts fell under the headings of Lean and Six Sigma. The basic concepts of process improvement have changed little over time but there has been such a proliferation of techniques and jargon that it can be a little confusing. Now we use terms like Continuous Improvement (CI) and Operational Excellence (OpEx) as a catch-all for anything related.

A few major themes are part of any OpEx endeavor, such as: what it works on, the techniques applied and how its organized. These attributes can be designed-in, or as is often the case, derived incrementally and ad hoc. This happens when one part of the business tries one approach, while another faction tries something different. Instead of resolving to a standard, the outcome is often the ‘tyranny of the OR’ where it’s hard to discern what is working and what is not. “Are we doing this, or are we doing that?”

Let’s look at these three themes in a little more detail.

The Focus of Operational Excellence

OpEx has two modes:

- Reaction – Responding to the most pressing issues of the day in areas such as productivity, quality, service and customer satisfaction.

- Prevention – Focusing on incremental improvements and sustaining; including process adherence and change management.

This is the right combination, but it’s pretty easy for organizations to get stuck in reactive mode and think of OpEx people as fire fighters whose main job is to put out fires instead of prevent them. This weakness can contribute to the downfall of OpEx when times get tough. Then, the biggest issue may be cutting cost and OpEx is often a cost that gets cut early. The up and down behavior makes it even tougher for the OpEx function to take off each time there is a restart.

Operational Excellence Techniques Applied

Tool kits includes things like: Lean, Six Sigma, manage change, coach, facilitate, deploy policy, map value streams, define standard work and conduct kaizen events and workshops, etc. That’s a pretty big list. Organizations often attempt to include too many tools and end up doing few of them well. Efforts can feel disjointed because they are. This is an area where the need for tool selectivity and standards guided by OpEx governance is obvious, but often lacking.

Differences in techniques applied across various industries have less to do with type of industry and more to do with the plethora of opinions, experiences, and competing priorities. For sure, a variety of techniques are expected and one size does not fit all. But wherever people and process come together, while the vocabulary and examples change, waste elimination and variation reduction methods don’t differ too much. Moreover, the methods and structures that deal with behaviors, engagement and change management are always the same.

OpEx Can Be Organized In Several Ways

Maybe the most obvious shift in recent years is the rise of OpEx as a legitimate internal function. This means that, at the very least, people are identified on an organization chart. Assigning resources is a good thing, but the amount of variability in how talent is applied suggests too much experimentation. Models include:

- Corporate Owned – Resources are sponsored by headquarters and mostly directed from there

- Operating Unit Owned – Resources are sponsored by and embedded within the operating units

- “Spray and Pray” – Broad skilling of associates without requirements for immediate application

- “Hammer and Nail” – Attack obvious problems with available resources, often with limited tools and experience

In practice it’s typically a combination of all of the above. The ratios shift over time as organizations learn and politics play out. Striking the right balance is essential for OpEx effectiveness. Articulating governance, communication and how people engage are all critically important.

In practice it’s typically a combination of all of the above. The ratios shift over time as organizations learn and politics play out. Striking the right balance is essential for OpEx effectiveness. Articulating governance, communication and how people engage are all critically important.

A Systems View of Operational Excellence

The themes noted here – targets, techniques, organization – should be familiar to anyone who has worked on or inside of OpEx. It’s easy to get caught up in organization charts, tools and the “fires”. When this happens, focus narrows and we miss the opportunity to engage broadly across the entire enterprise.

Operational excellence is not a function. It is a RESULT that is best achieved by an OpEx SYSTEM that engages everyone.

Effective OpEx systems balance corporate and operating unit needs, target urgent problems and prevent others from ever occurring. They define, and then use, standard work to get things done. Reporting, capturing best practices, communication and sharing information is described, done and enforced. These are the things the OpEx function should be working on.

Broad organizational involvement and commitment is perhaps the most obvious benefit of a robust OpEx system. Leveraging the knowledge and input of those closest to their work shows respect for people and drives decision-making to the lowest possible level – a key tenant of an improvement culture. A fully engaged organization achieves relevant results, gains traction and becomes a sustainable continuous improvement engine. When the OpEx system is designed and defined, its performance can be evaluated and improved. A good OpEx system is:

- Simple – The easier it is to understand, the easier it is to see if people are doing it

- Engaging – Everyone participates. Ownership and expectations are articulated

- Actively Managed – Leaders are hands-on in guiding the change process

- Structured – The way the organization is expected to interact is clearly defined

Don’t over-complicate it. Too many rules lead to unwarranted bureaucracy and can kill beneficial creativity. If design and definition become the major focus, no one will ever get out of the blocks and actually start fixing things. Balancing standard requirements with creative and flexible problem-solving is one of the great challenges. Sorting that out creates a sense of ownership and develops the organization.

Don’t over-complicate it. Too many rules lead to unwarranted bureaucracy and can kill beneficial creativity. If design and definition become the major focus, no one will ever get out of the blocks and actually start fixing things. Balancing standard requirements with creative and flexible problem-solving is one of the great challenges. Sorting that out creates a sense of ownership and develops the organization.

As people should be at the heart of any OpEx system, start by describing the critical few things that demonstrate personal participation and then link these elements to recognition and reward. This is just one of many small steps that the enlightened enterprise goes through to become operationally great. It can be done once leaders decide that operational excellence is a literal objective and OpEx is a system for engaging the organization instead of a check the box function or a quick-fix for the crisis du jour.

Want to read more on topics like this? Head over to our Knowledge Center to get access to our full catalog of white papers.

Transform and Sustain: Three Rules for Better Results

/in Engagement, Leadership /by Jerry TimpsonNothing is Transformed if it Cannot be Sustained

Clients never say: “We want to transform and do better, but we don’t care if we sustain the improvements.” Clients always profess a sincere desire to sustain results. This intent is so pervasive that during the past 20 years we’ve seen the rise of Operational Excellence as a legitimate function across wide swaths of business and industry. Yet most organizations fail to realize this apparently lofty goal. Low levels of lasting success are usually explained at a tactical level, but the reasons that leaders and their organizations get it wrong goes much deeper.

Clients never say: “We want to transform and do better, but we don’t care if we sustain the improvements.” Clients always profess a sincere desire to sustain results. This intent is so pervasive that during the past 20 years we’ve seen the rise of Operational Excellence as a legitimate function across wide swaths of business and industry. Yet most organizations fail to realize this apparently lofty goal. Low levels of lasting success are usually explained at a tactical level, but the reasons that leaders and their organizations get it wrong goes much deeper.

To get a handle on what is happening and why, we explore some of the traditional norms, individual behaviors and corporate incentives that must be rethought to enable transformation success. As a first step, let’s define a few simple rules that are the foundation of any successful initiative:

Rule 1 – The Environment IS Dynamic

It’s obvious to say, but our environment is dynamic. Everything changes all the time. “Sustain” conveys a sense of holding something – a process or procedures for example – in place. It’s time to re-evaluate this concept and acknowledge that in a dynamic environment, sustain doesn’t mean we pin something to the ground. Rather, it means we stay in lock-step with a moving target, consistently and credibly adjusting and improving.

Rule 2 – Understanding Value

Value is best understood where it is created. People know the most about optimization of the things they work on. Even more important, people care more about the things they work on than the things they don’t. Failure to grasp this rule is why top-down control of improvement systems doesn’t work well and never lasts.

Rule 3 – The Leader’s Role

For any of this to work – meaning, ongoing improvement and sustainment ̶ the organization must be engaged and stay engaged. In simple terms:

More Engagement Equals Better Results

A primary (perhaps the primary) function of leadership is to compel engagement. Easier said than done, we can state flatly that engagement is an activity that can be measured and when it’s missing, overtly addressed. Experience tells us that if engagement is not compelled, it will not happen enough to deliver lasting improvement.

When everyone works on solutions with cadence, structure and discipline, peers are required to spend time together improving their deliverables along the value stream. Team dynamics increase accountability and generate performance momentum. This is the catalyst for sustainment.

Internalizing and applying these rules to any improvement system increases the odds of success. Fail to apply them and results will be sub-optimized at best. Going to the next level requires understanding the underlying organizational behaviors that come into play in the struggle to transform and sustain. Here they are:

Engagement is Not Understood or Valued

The building blocks of lasting transformation revolve around getting and keeping everyone engaged (Rule #3). Unfortunately, organizational dynamics and behaviors that deliver this are seldom experienced or even witnessed. And, “What good looks like…” is rarely part of one’s education or training curriculum. Understanding the structure of engagement so that it can be baked into the DNA of the system is essential to going beyond the “what” of transformation and getting to the “how” of it.

How to Sustain is Not Defined

In some respects it is difficult to separate transformation and sustainment. They are two sides of the same coin. But if we see engagement as the glue that holds these concepts together, it deserves a definition that is simple enough to act upon. Therefore:

The organization is engaged when you, your peers, your superiors and subordinates spend at least one hour each week actively improving the business.

This is what good looks like. When you overtly define engagement at an individual level, the behaviors and actions of it can be observed, measured and mirrored. Too often, leaders want everyone to really “get it” before they do it. Transformation happens in the reverse.

For Many, Putting Energy Into Sustaining Activities Doesn’t Pay

Transformation initiatives most often occur inside a business emergency. During these times, communication spikes, teams are formed, actions are chartered and things get done. It feels great! When it’s over, the quorum disengages, momentum wanes and everyone reverts to business as usual. The final step is recognition and reward conveyed for fixing the crisis. Big changes, big projects, and big results – these are the things that get noticed and rewarded. Everyone working on small, incremental changes and improvements for the better? … Yawn.

When the requirements for sustainment are poorly defined, not well understood and appear difficult to measure, they are avoided. Success requires broad participation, openness to new ideas and a convergence of standard, simple mechanisms aimed at improving the business. Overtly make the connection between transformation and sustainment, then weave it into the compensation, reward and recognition system. Make it safe and make it pay.

Proactive Problem Solving Might Seem Simple and Boring… and People Are Easily Distracted

The concepts and execution requirements described here are so simple that they are easily dismissed. The ideas of broad inclusion and a flatter organization often require a significant re-evaluation of organizational norms and are naturally avoided. Any distraction; the latest crisis, a new technology or any approach or method that might require less coaching and change management is a welcomed relief. Without some overt activities that demonstrate our adherence to engagement, most will shift away – usually with the tacit approval of their bosses who never got it in the first place.

It Disrupts the Status Quo

When engagement and sustainable transformation starts to occur, decisions are pushed down in order to optimize absolute value. This is a shift that challenges well-established networks that are built around personal relationships and existing dynamics. It’s disruptive. This above all others is the biggest reason for failure.

The truth is this shift frees energy that is traditionally spent on re-work, redundancy and errors. Not everyone will see it this way but when the new system of engagement is well defined and well structured, resistance is easily surfaced. Shifts in organizational and personal behavior are required. Recognize the fact that something that threatens entrenched relationships and systems succeeds only with a crystal-clear mandate, a well-defined plan and adequate coaching.

With all these obstacles, it’s no wonder the majority of organizations and leaders lament an inability to sustain their transformation and continuously improve. Start by viewing the system holistically with a keen eye on organizational dynamics, individual behaviors, simple definitions and an approach that is firmly linked to activity-based performance measures. This will help avoid rework that is exponentially more difficult the second, third, and fourth time through.

**********

For information about how to engage workgroups and push decision making down, read about Kaufman Global’s Lean Daily Management System.