The Lean Daily Management System Part 4 | The 20 Keys

What if every workgroup within your enterprise could develop and manage its own improvement plan?

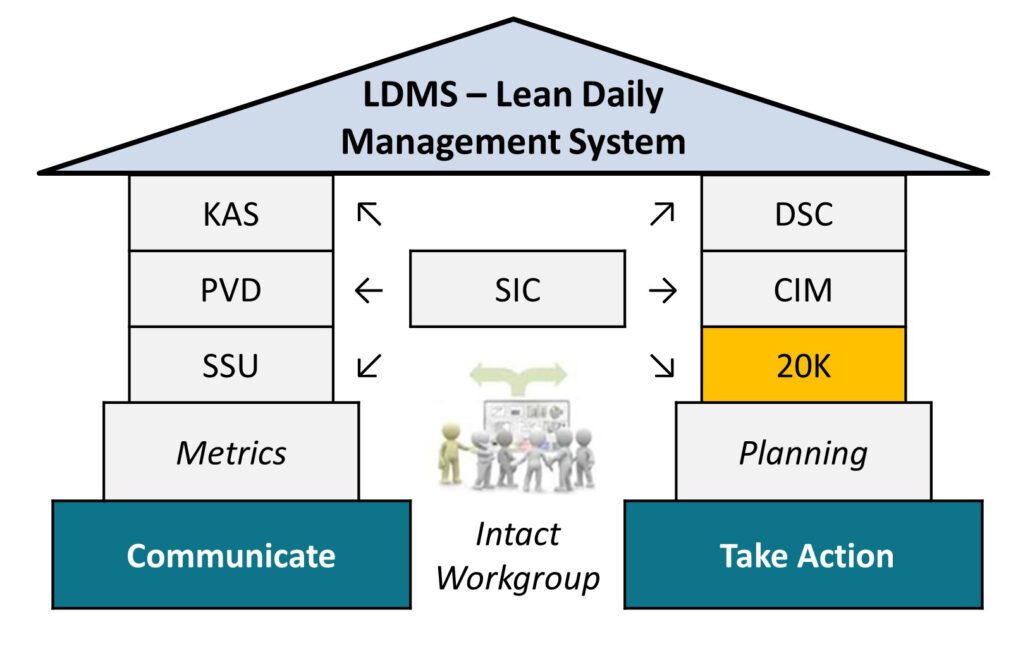

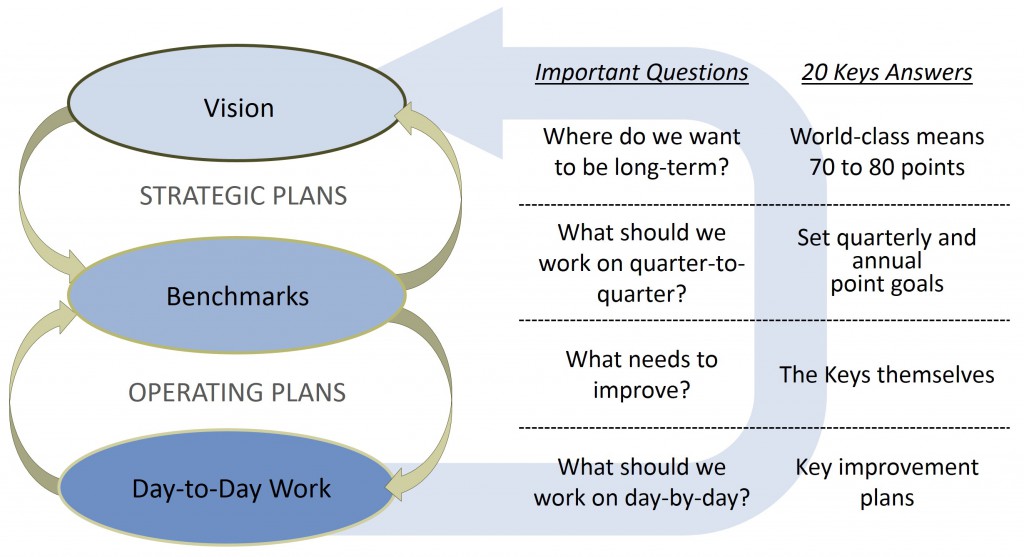

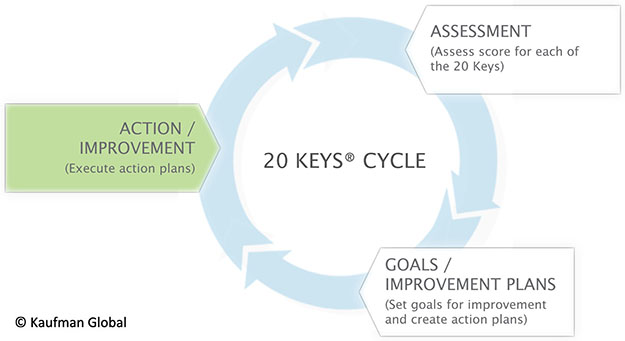

Description: In the Lean Daily Management System (LDMS) post Part 4, we’ll move on to take a look at the 20 Keys (LDMS framework inset right). Applying the 20 Keys helps individual workgroups evaluate and understand their own performance, then develop a structured long-term improvement plan for their specific situation (20 Keys cycle inset below). While leadership or third-party resources often help with an initial assessment, many believe that the fact that 20 Keys becomes a self-assessment — that is, the keys are evaluated and acted upon by a workgroup who rates and pushes themselves — is likely to be the most important aspect in its success through compelling buy-in and ownership. Moreover, the plain language quality of the keys means that the key’s level-descriptions really can’t be gamed; something simply doesn’t smell right when reality and numbers don’t track.

right). Applying the 20 Keys helps individual workgroups evaluate and understand their own performance, then develop a structured long-term improvement plan for their specific situation (20 Keys cycle inset below). While leadership or third-party resources often help with an initial assessment, many believe that the fact that 20 Keys becomes a self-assessment — that is, the keys are evaluated and acted upon by a workgroup who rates and pushes themselves — is likely to be the most important aspect in its success through compelling buy-in and ownership. Moreover, the plain language quality of the keys means that the key’s level-descriptions really can’t be gamed; something simply doesn’t smell right when reality and numbers don’t track.

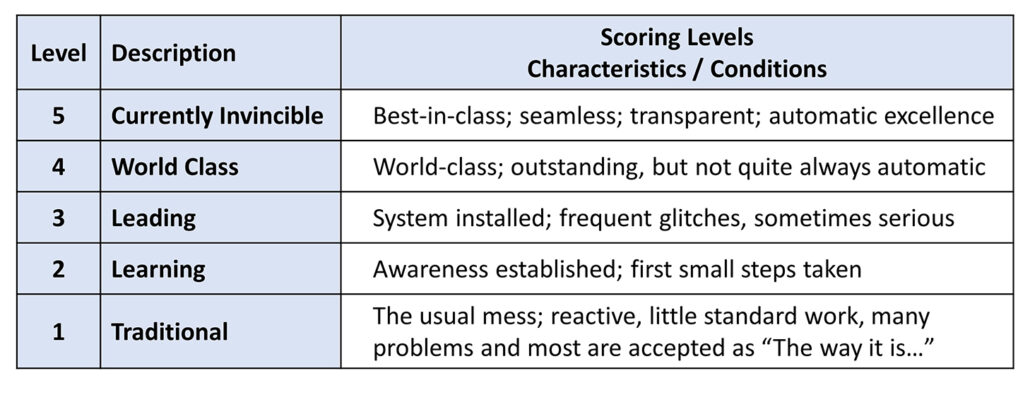

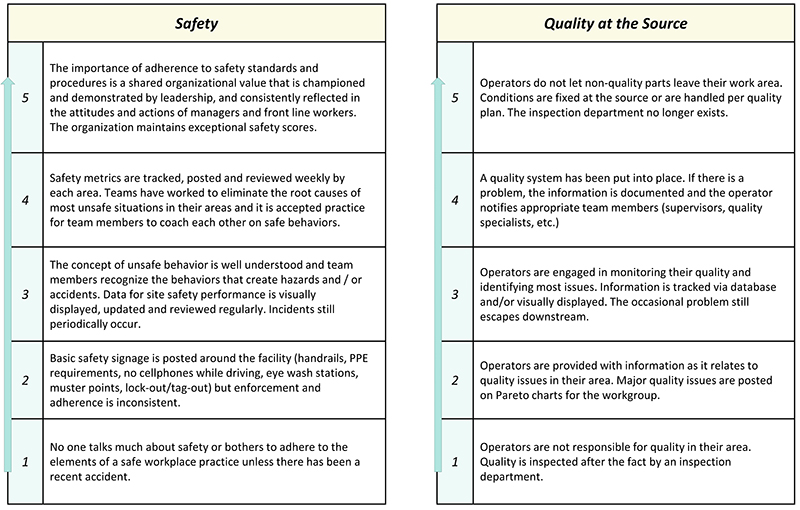

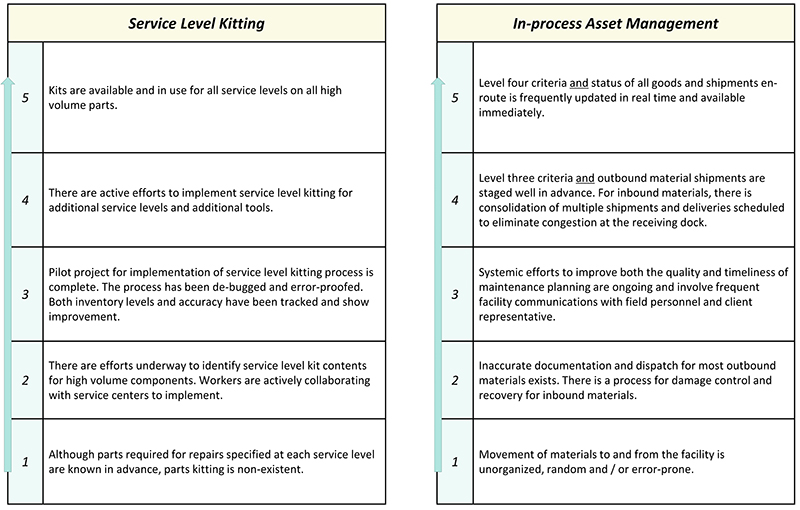

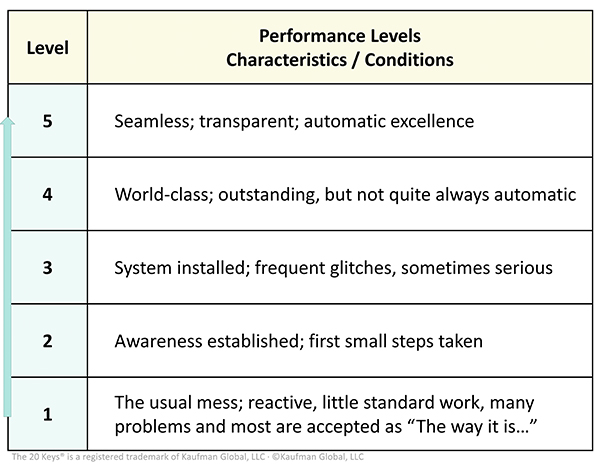

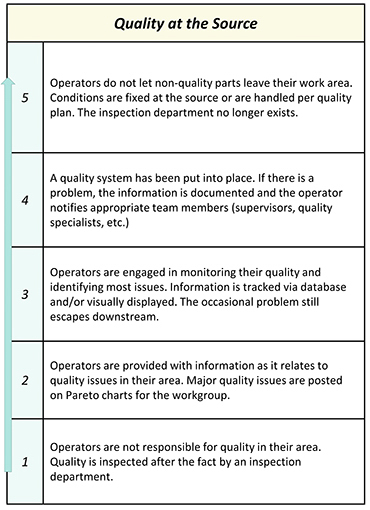

About the Process: Utilizing 20 Keys is intuitive. It depicts op erational or functional work areas (ex.: manufacturing or materials management) in 20 “key” elements (ex.: error-proofing or problem-solving) whose descriptions reflect steps toward world-class performance benchmarks. For each key, five performance ranks are described in plain language beginning with a Level 1 – Traditional through Level 5 – Currently Invincible (table inset below).

erational or functional work areas (ex.: manufacturing or materials management) in 20 “key” elements (ex.: error-proofing or problem-solving) whose descriptions reflect steps toward world-class performance benchmarks. For each key, five performance ranks are described in plain language beginning with a Level 1 – Traditional through Level 5 – Currently Invincible (table inset below).

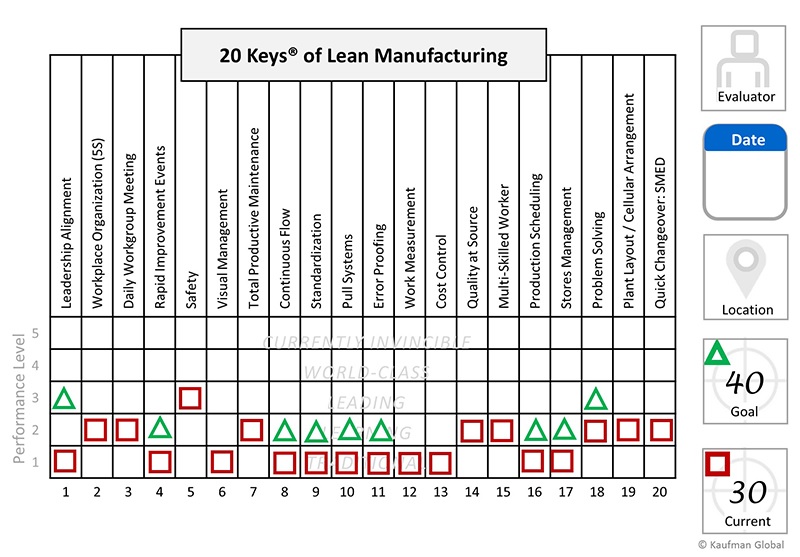

Completed 20 Keys data packs consist of: a chart mapping goal attainment; a corresponding set of point or level descriptors for individual keys; and, a workgroup devised and maintained action plan detailing who does what by when in order to achieve workgroup improvement aims. Overall, a starting point is no less than 20 points (1 point earned for “traditional” in each key) and 100 points is the maximum achievable. Improving 10 points per year in early years is doable. Workgroups having achieved 60 points tend to look and feel fantastic and are quite high-functioning. Although it can happen, we don’t encounter many workgroups over the low 80s.

Completed 20 Keys data packs consist of: a chart mapping goal attainment; a corresponding set of point or level descriptors for individual keys; and, a workgroup devised and maintained action plan detailing who does what by when in order to achieve workgroup improvement aims. Overall, a starting point is no less than 20 points (1 point earned for “traditional” in each key) and 100 points is the maximum achievable. Improving 10 points per year in early years is doable. Workgroups having achieved 60 points tend to look and feel fantastic and are quite high-functioning. Although it can happen, we don’t encounter many workgroups over the low 80s.

The graphic (inset below) depicts a 20 Keys chart for a manufacturing cell where the current score (squares) is 30 out of 100. Triangles represent the workgroup’s improvement goals for the individual keys they’ve selected to improve at this time for a 40-point total targeted within six months. A key-by-key improvement plan (not shown) is prepared listing the specific tasks required by workgroup members to attain the point goals.

In order to level-set, monitor and review continuous improvement progress, there’s no better approach than Kaufman Global’s 20 Keys®, a proprietary method focusing intact workgroups on the vital dimensions of how it operates versus world-class benchmarks. Transcending both language and culture, organizations worldwide have implemented 20 Keys with sustained success. Kaufman Global has developed over 25 different sets of keys applicable to operational and functional settings, including Customer Service, Supply Chain Management, Engineering and Project Management. Regardless of which sets are used, 20 Keys relays a standard approach to evaluate and improve performance effectiveness throughout your enterprise.

In order to level-set, monitor and review continuous improvement progress, there’s no better approach than Kaufman Global’s 20 Keys®, a proprietary method focusing intact workgroups on the vital dimensions of how it operates versus world-class benchmarks. Transcending both language and culture, organizations worldwide have implemented 20 Keys with sustained success. Kaufman Global has developed over 25 different sets of keys applicable to operational and functional settings, including Customer Service, Supply Chain Management, Engineering and Project Management. Regardless of which sets are used, 20 Keys relays a standard approach to evaluate and improve performance effectiveness throughout your enterprise.

Next Time

Thanks for your attention to this 20 Keys summary! In Part 5, we’ll cover Short Interval Coaching. In the meantime, if you’d like to start your LDMS workgroups off right – or, if you’ve already started and you aren’t getting the expected results, we can help course correct. Kaufman Global offers you: deep, real-world experience, world-class coaching and training at all levels, a rich array of intellectual property, learning materials, and Train-the-Trainer Certification programs all focused on solving actual performance problems so you get a business result while creating organization capability. For immediate attention, don’t hesitate to reach out.

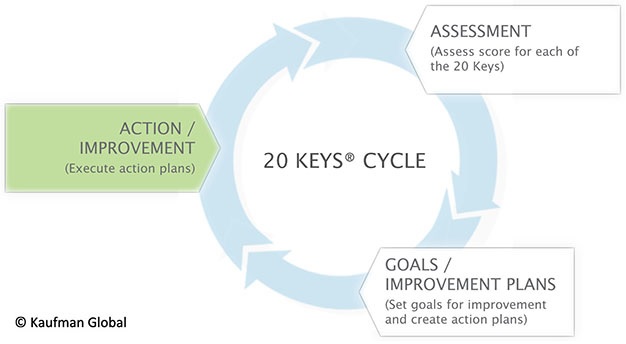

As identified in the 20 Keys Cycle illustration above, the method drives a continuous cycle of improvement and builds on prior efforts. Typically repeated four times per year, location leadership or a designated representative works with the workgroup to assess their score for each of the 20 keys. This is an honest, direct exchange in which the they score each key against known criteria. Once the assessment is done, this same workgroup decides on which key(s) they should focus on improving. The objective is for them to increase their overall score by 10 points per year.

As identified in the 20 Keys Cycle illustration above, the method drives a continuous cycle of improvement and builds on prior efforts. Typically repeated four times per year, location leadership or a designated representative works with the workgroup to assess their score for each of the 20 keys. This is an honest, direct exchange in which the they score each key against known criteria. Once the assessment is done, this same workgroup decides on which key(s) they should focus on improving. The objective is for them to increase their overall score by 10 points per year.