Single Piece Flow

Single piece flow is the movement of a single element of production along a production line or process.

Also referred to as one-piece flow, it is an optimized configuration of work that, when compared to batch production methods, serves to minimize inventories and the time required to produce product. With single piece flow, items proceed through the various stages of production one at a time without:

- the need for huge amounts of raw materials (RM) to feed work stations

- accumulation of a great deal of work-in-process (WIP), or

- resulting overproduction of staged, interim transfer lots.

All of these things add cost.

Minimizing RM and WIP while eliminating the transfer of bulk material requires less floor space and fewer pieces of high-capacity handling equipment to move. Avoiding such voluminous material movements contributes to a safer workplace. Focus on a single piece readily enables in-process defect detection before a significant item quantity is produced with the same flaw. Along with this heightened level of quality awareness, workers often become more engaged with ongoing tasks which leads to greater job satisfaction.

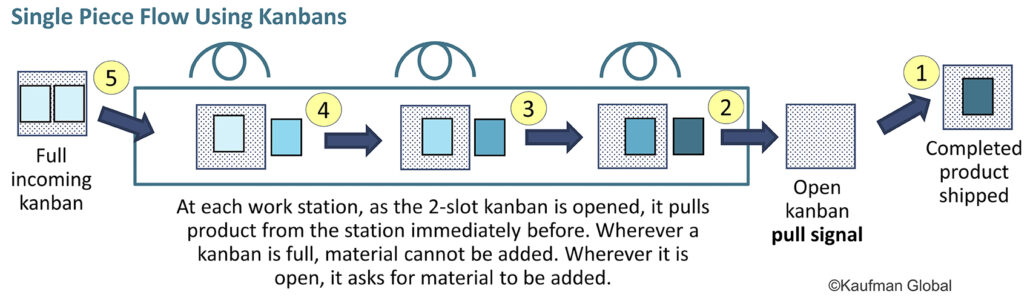

While not the only manner in which to pace production in every circumstance, when single piece flow is thoughtfully implemented with complementary lean concepts such as cellular production, kanban (pull systems) and workplace organization, continuous flow to the customer’s demand rate (takt time) is efficiently achieved and readily sustained. With today’s emphasis on service delivery inside an information economy, many have successfully adapted and applied what were originally operational concepts within government, health care, procurement and insurance functional sectors where knowledge workers are employed and the “product” may be a document.

« Back to Glossary Index