Kaizen Event

The Kaizen Event (KE) is a standard approach to team-based problem solving. The KE helps teams focus on process problems that are beyond the day-to-day work. The Kaizen Event is a fundamental and popular Operational Excellence technique.

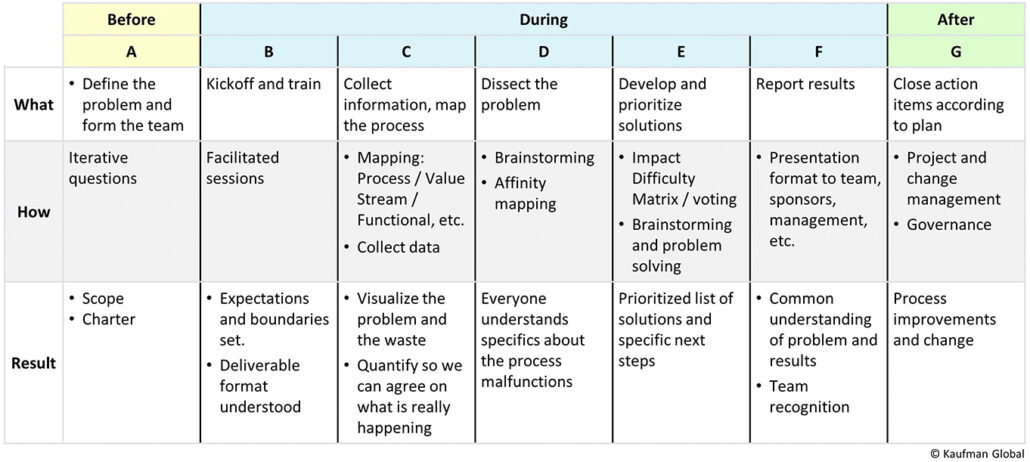

Kaizen Event Approach

Kaizen Events are highly facilitated sessions that bring a team together, usually 5 to 9 individuals who work within the process along with representatives from upstream (suppliers) and downstream (customers). The standard sequence of events is:

- Define the scope and form the team

- Kick off the event and train the team in the basics (Lean, waste, problem solving, teamwork, etc.)

- Map the process and collect data

- Dissect the problem into its elements

- Develop and prioritize solutions

- Report results

- Close action items according to plan

The work utilizes an array of Lean and OpEx tools and techniques. Kaizen Event workshops are chartered with a tightly defined scope and usually last between 3 and 5 days. They includes real-time training, an executive champion and a final report-out to interested and affected parties.

Basic Steps For Any Kaizen Event

Kaizen Event Scope

The KE can be applied to any process problem – manufacturing, business process or service. It is important to limit the scope to something that a small team can tackle in a week or less of highly focused process improvement work. Lean and process improvement techniques such as Value Stream and Process Mapping, and Hand-Off Charts and RACI Diagrams are often applied during the Kaizen Event.

The Top 10 Rules of Successful Kaizen Events

- Reject current situation

- Take action over excuses

- Make workplace and problems visible

- Get on base rather than go for the long ball

- Correct mistakes immediately

- Use your head rather than your money

- Destroy myths of fixed production ideas

- Make actual improvements now … (Bias-for-action)

- It’s a never-ending task

- Ask why? To find out real answers

Notes:

Want more detail? A three-week guide to Kaizen Event planning, conduct and follow-up can be found here in our Kaizen 101 blog post.

Find out more about how to really make the Rapid Improvement Event (also known as Kaizen Event) work in this exciting blog post: Rapid Improvement Event Fundamentals

To learn about Kaufman Global’s related services, go here: Kaizen Events

Other names for the Rapid Improvement Event: Kaizen Event, Accelerated Change Process (ACP), Work Out, Change Acceleration Process (CAP), Process Improvement Process (PIP) and the list goes on.

« Back to Glossary Index