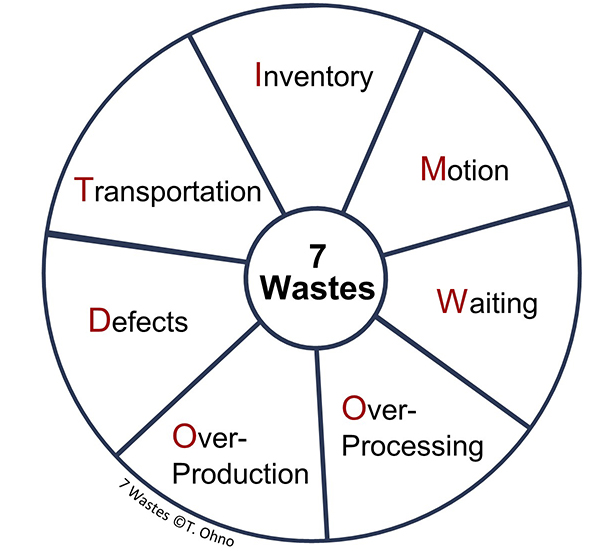

7 Types of Waste (Muda)

The 7 wastes in production systems are:

- Transportation – Moving things; shipping, conveyors (materials, equipment, people)

- Inventory – Storing, sorting, clutter, obsolescence

- Motion – Unnecessary movement of people and equipment

- Waiting – Idle time, including waiting for equipment, material or processes to be complete

- Over-Processing – Unnecessary steps in the production process

- Over-Production – Making too much

- Defects – Rework and scrap due to poor quality

These were first defined by Taiichi Ohno, the father of Lean in manufacturing operations. Waste is defined as anything that uses resources, but does not add real value to transforming the product or service. We show here the original 7 Wastes in Taiichi Ohno’s Waste Wheel configuration. It is arranged in the popular TIM WOOD mnemonic. Muda is the Japanese term for waste.

An 8th type of waste is often added to this scheme – that is the waste from unused human capital, sometimes also referred to as: People Waste, Talent Waste, Intellect Waste, Creativity Waste and so on… It is basically a way of indicating that engagement is important.

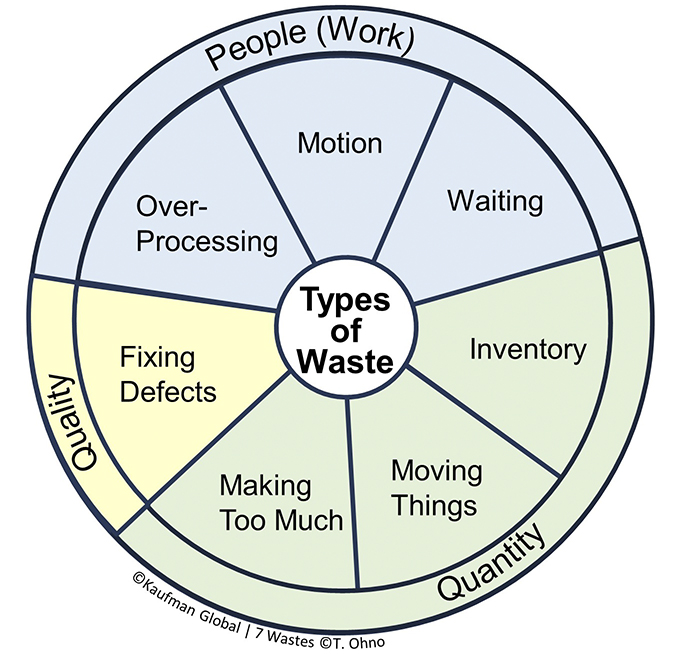

Kaufman Global prefers a different configuration of the traditional 7-Waste wheel. It is shown here. We prefer this for two reasons:

- Waste is labeled in a way that exactly describes the thing that is causing the waste. For example, Defects themselves are not the waste, fixing them is. And,

- We can categorize the wastes in a way that helps us see the groupings of People Work, Quality and Quantity – which provides a clearer path to waste elimination.