Total Productive Maintenance

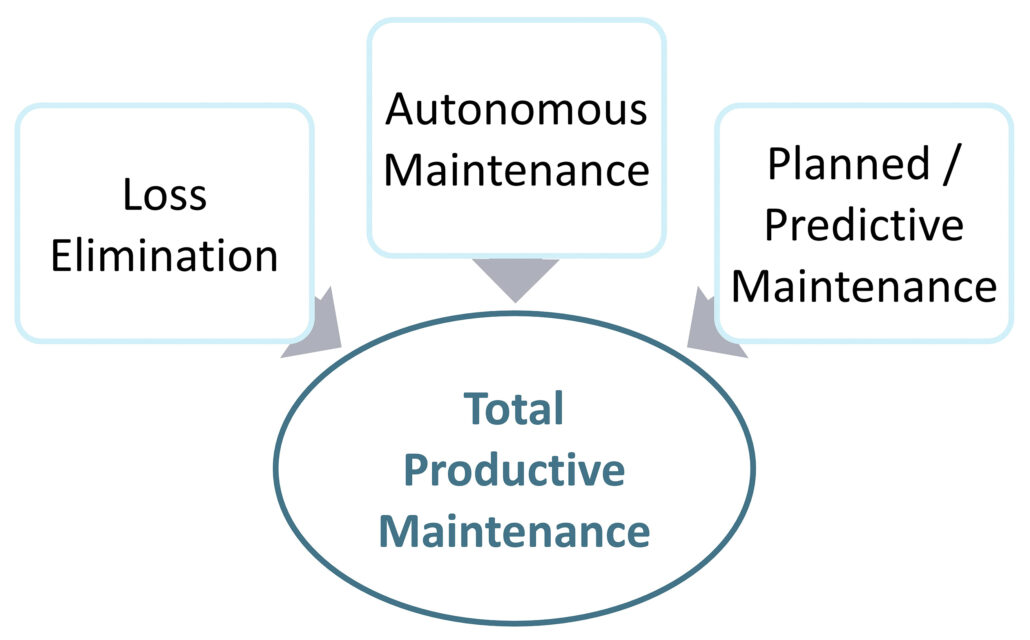

Total Productive Maintenance (TPM) is a series of methods to ensure that every machine in a production process is always able to perform its required tasks through improved equipment availability and uptime. TPM has three major elements: Loss Elimination, Autonomous Maintenance and Planned / Predictive Maintenance. Each element has its own set of techniques and approaches.

- Loss Elimination: Maintenance, design engineers and production engineers and operators work together to eliminate the six major types of losses:

- Set-ups and adjustments

- Breakdowns

- Idling and minor stops

- Start-up / yield loss

- Defects and rework

- Reduced running speed

- Autonomous maintenance: Operators are involved in maintaining their own equipment. They participate by conducting initial cleaning (5S), making cleaning and inspection easier, setting cleaning and lubrication standards, developing general inspection skills, and conducting daily cleaning and inspection.

- Preventive and predictive maintenance: Maintenance teams conduct daily and periodic maintenance and inspection, predictive maintenance (using technologies that determine “when” something is going to break), improvements to lengthen equipment life, spare parts control, breakdown analysis and lubrication control.

The key measure for Total Productive Maintenance is Overall Equipment Effectiveness (OEE). OEE is the time that an asset (machine) is producing product versus the theoretical maximum amount of time the equipment could be producing.

TPM is based on employee participation and standard work. Teamwork skills and flexibility are improved between operators and maintenance personnel as operators perform planned maintenance and maintenance staff spend less time fire fighting.

« Back to Glossary Index