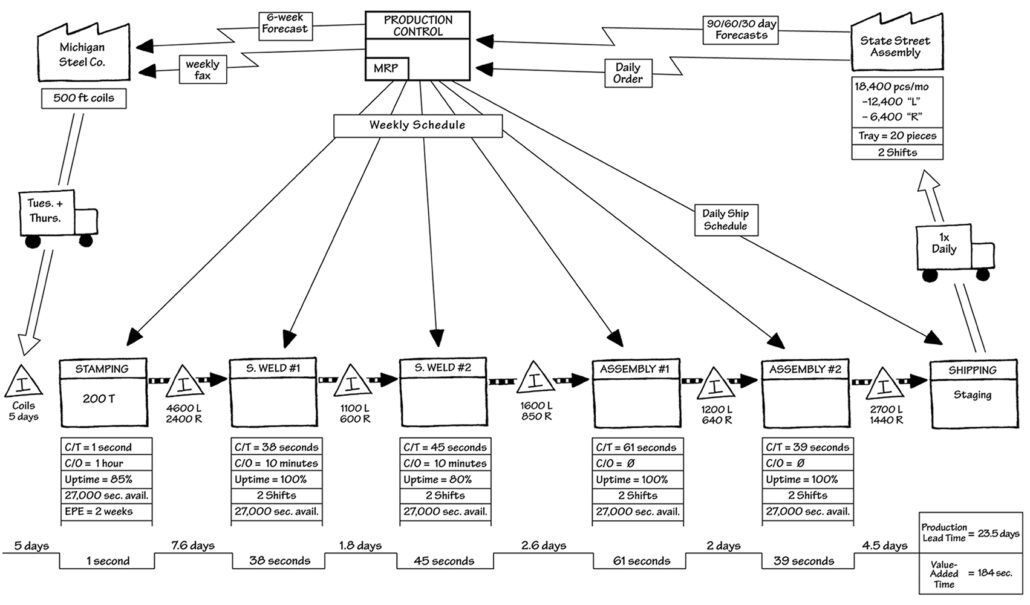

Value Stream Map

A Value Stream Map (VSM) is a graphical format used to describe a process or series of processes that deliver products and services to customers. The VSM is that it shows a flow of information, materials and activities that work together to move materials through the various activities of a production process.

Value Stream Maps tell you what you have (materials, components, inventory), why you have it (production control, pull signals, etc.) and how efficient the process is (cycle time, value added time, lead time). By mapping this information in a standard format, we can begin to see where waste and value reside inside the system.

The VSM uses mostly standard icons to describe processes, transportation, inventory, etc. But remember, the objective of all maps is to tell a story. So you should use whatever helps convey the message of flow, inventory and process.

Why Use a Value Stream Map?

- It serves as a communication tool

- It highlights the sources and areas of waste in the value stream

- It shows the linkage between the material and information flows

- It integrates Lean concepts and principles in the future-state design

- It forms the basis of the implementation plan to implement the change to the future state

VSMs are most useful to describe and visually see what is happening with the current state inside a macro-process. From here, we can see issues and problems and develop a prioritized list of opportunities to improve flow through the value stream.

Future State value stream maps are used showing process steps and streamlining flow. These are opportunities to develop various scenarios for improvement.

Value stream maps can be constructed in a couple of ways. One way is to go directly to the Gemba, observe each step of the process and consolidate all of the data that describes the current state. Another way is to convene a VSM team and ask them to bring the data as well as their experience about what really happens inside the process. This approach is typically faster and equally reliable.

For more information on Value Stream Mapping, get the book Learning to See by John Shook.

« Back to Glossary Index