Mass Production

Mass production delivers large quantities of standardized products. It uses assembly lines, automation and batch processing to maximize productivity and efficiency. The term was popularized in the 1920s and is often associated with the assembly lines of Ford Motor Company. But really, the concept has been around for centuries. Mass production can be contrasted to:

- Craft production where specialists produce individual products, typically one at a time, and

- Lean production where product is pulled through the system (a single unit at a time if possible) with a bias for low inventory

Mass production might be applied to any production operation that seeks to maximize output. Hallmarks include:

- Little variation or customization of product

- Willingness to accept higher inventory (and higher levels of rework)

- Push systems that “push” production requirements into the production area(s)

“Any customer can have a car painted any color that he wants so long as it is black.”

~Henry Ford issued this statement in 1909.

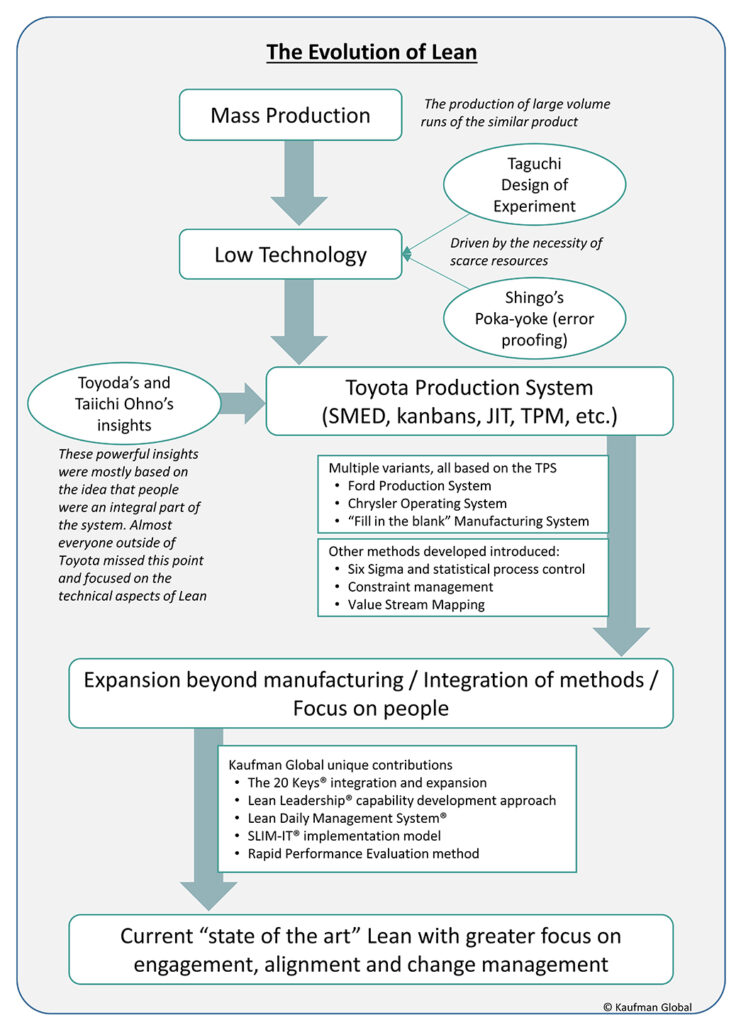

Mass production and it’s relationship to the evolution of Lean is shown in the diagram below: