Just In Time

Just In Time (JIT) is the concept and practice of moving products and services through the production and delivery processes so as to minimize inventories and related wastes. Just In Time is the philosophical and practical foundation of all lean systems and one of the founding principles of the Toyota Production System.

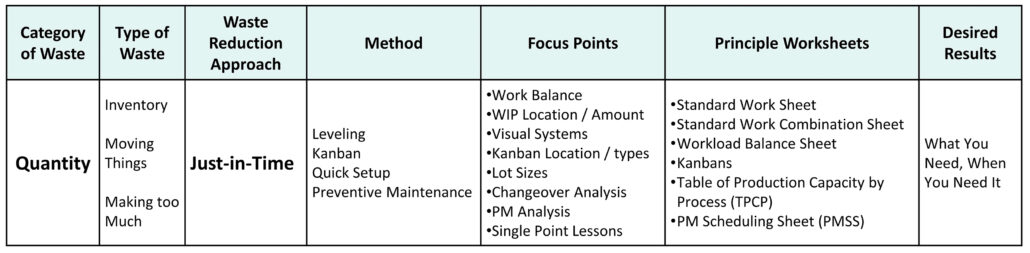

As its name implies, everything moves through a series of processes only as needed. Lead times are reduced and inventories minimized. Almost every operational excellence technique available contributes to JIT results. The primary focus is on quantity and the chart below shows some of the relationships between objectives (minimize quantities and maximize flow through the value stream) and techniques.