6Ms of Production (man, machine, material, method, mother nature and measurement)

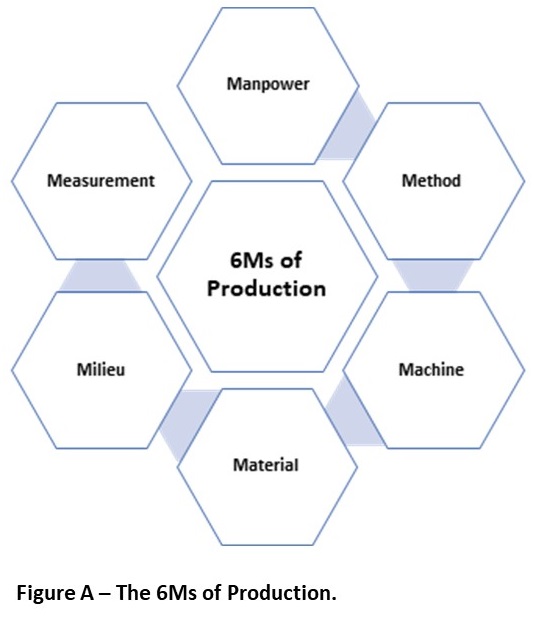

The 6Ms of production – Manpower, Method, Machine, Material, Milieu and Measurement – is a mnemonic representing the characteristic dimensions[1] to consider when brainstorming during “cause and effect” problem-solving sessions. Capture and bin the issues (causes) under the 6M categories. Once documented, place the causes according to category on a cause and effect diagram [2]. Develop improvement plans starting with the most significant issues first. When we think in terms of categories, it helps us separate and then rank the specific causes for various effects and problems.

Question: We could use your help – seriously. We (Kaufman Global) get a ton of traffic on this web page – about 5x more traffic on this page than any other. I would appreciate some insight – can you tell me if you searched for a specific term that took you to this page or, if you searched for something else and you somehow landed on this page? Thank you so much for any insight. I can be emailed at jtimpson@kaufmanglobal.com – Jerry

The 6Ms of Production

One important tool in this methodology is an Impact Difficulty Matrix. This technique determines the potential impact of each solution and the difficulty of implementing the solution. By ranking solutions in this way, the easiest to do with the least amount of effort, rise to the top of the list for implementation.

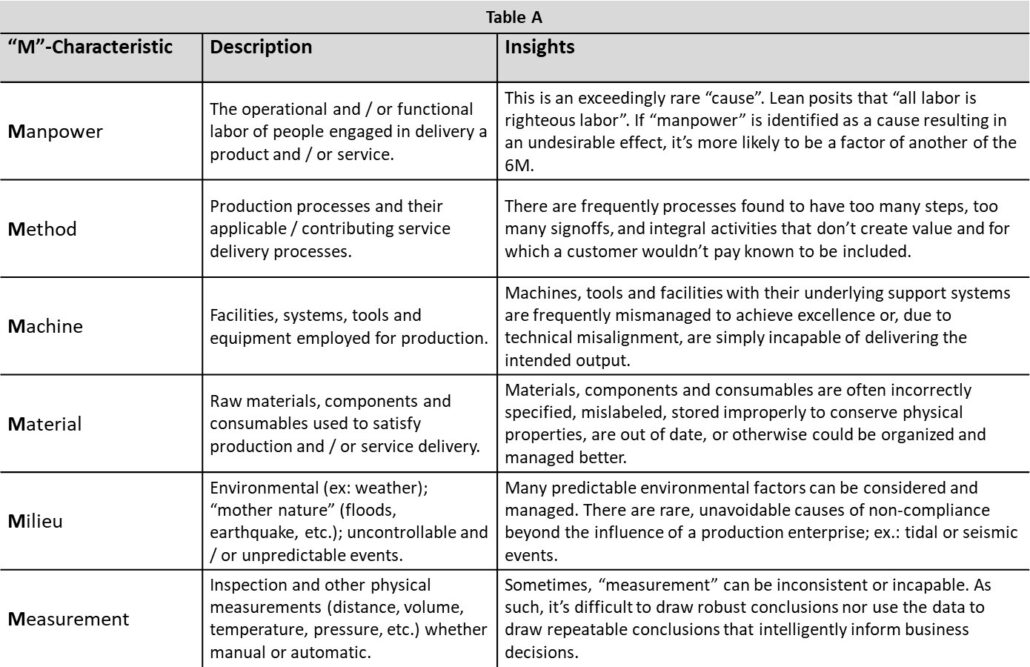

6M Characteristics, Description and Insights:

Notes:

[1] In an information economy with knowledge workers, this also comprehends the notion of discrete and / or supporting “service” delivery.

[2] Understanding how these factors impact the process and the establishment of standards are key steps in strengthening production processes. The 6M factors are used to construct cause-and-effect diagrams. Also known as a Fishbone Diagram due to its appearance (or, an Ishikawa Diagram as named after its developer, Kaoru Ishikawa). Example in Figure B below.