5S System for Cleaning and Organizing

5S is a formal method for cleaning and organizing a workplace. It is a sequence of steps that move from chaos to order to eliminate waste and improve flow. The technique is especially effective for shared areas like a shop floor or offices. The S’s are derived from these Japanese words:

seiri = sorting: Going through all tools, materials, etc., in the work area and keeping only essential items. Everything else is stored or discarded. This leads to fewer hazards and less clutter to interfere with productive work.

seiton = simplifying, or straighten: Focuses on the need for an orderly workplace. “Orderly” in this sense means arranging the tools and equipment in an order that promotes workflow. Tools and equipment should be kept where they will be used, and the process should be ordered in a manner that eliminates extra motion.

seisō = sweeping, systematic cleaning, or shining: Indicates the need to keep the workplace clean as well as neat. Cleaning in Japanese companies is a daily activity. At the end of each shift, the work area is cleaned up and everything is restored to its place, making it easy to see what goes where and to know when everything is where it should be. The key point is that maintaining cleanliness should be part of the daily work – not an occasional activity initiated when things get too messy.

seiketsu = standardizing: This refers to standardized work practices. It refers to more than standardized cleanliness (otherwise this would mean essentially the same as “systemized cleanliness”). This means operating in a consistent and standardized fashion. Everyone knows exactly what his or her responsibilities are, and time is built into their jobs to perform them. In part, this follows from seiton where the order of a workplace should reflect the process of work, these simply standardized work practice and work station layout.

shitsuke = sustaining: Refers to maintaining and reviewing standards. Once the previous 4Ss have been established, they become the new way to operate. Maintain the focus on this new way of operating, and do not allow a gradual decline back to old ways. Shitsuke is also about changing processes, equipment and individual behaviors to prevent disorganization and uncleanliness from occurring in the first place.

The 5S approach originated in Japan with the Toyota Production System and the S’s are abbreviations for Japanese words. They are sometimes described in English as “Cleaning and Organizing”. The underlying principle is that cleaning and organizing is a relatively simple first step in the Lean journey – and one that everyone knows something about already. Some companies add safety and call it 6S.The 5S method appears deceptive straight forward and it is, but maintaining a true 5S culture requires discipline and standard work. Often 5S audit processes help engage leadership and keep things on track.

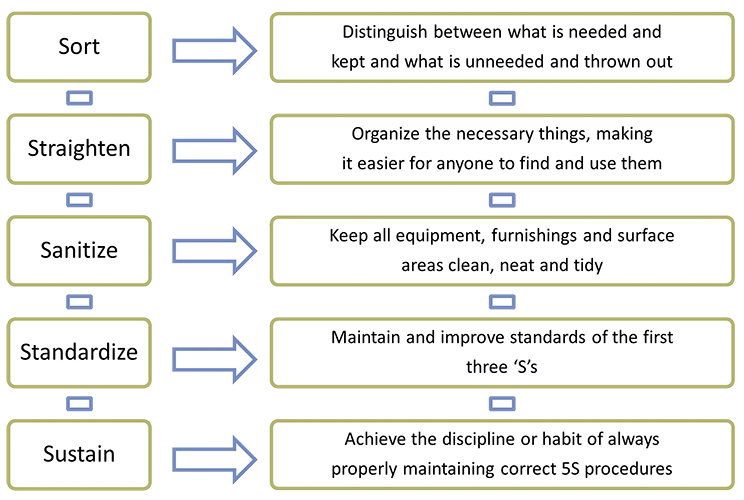

The 5S English definition equivalents are shown here: Sort, Straighten, Sanitize, Standardize, Sustain

Kaufman Global’s 5S Stand Down Event is described here and is a good way to jump-start cleaning and organizing activities in places that are in rough shape starting out.

« Back to Glossary Index