SERVICES

20 years of accelerating performance for clients worldwide: Fast Action | Fast Impact | Enduring Confidence

When it comes to implementing Lean, Kaufman Global knows how it’s done.

Lean Manufacturing is a leadership philosophy, a management system and a set of tactical tools that, when implemented, is the single-most powerful strategy for improving a production operation’s competitiveness.

The benefits of Lean can drive a wide range of outcomes, including:

- Reductions in material and process waste, inventory levels and quality defects

- Increased asset utilization, cycle time, throughput and overall capacity

- Enabled enterprise objectives such as aggressive cost reduction, growth and integration strategies

To achieve these kinds of results, we keep a few fundamentals front and center. We:

- Ensuring management shares the vision: What, How and Why

- Proactively address the organization’s natural resistance to change

- Develop a complete strategy that integrates the use of tools and change-management approaches

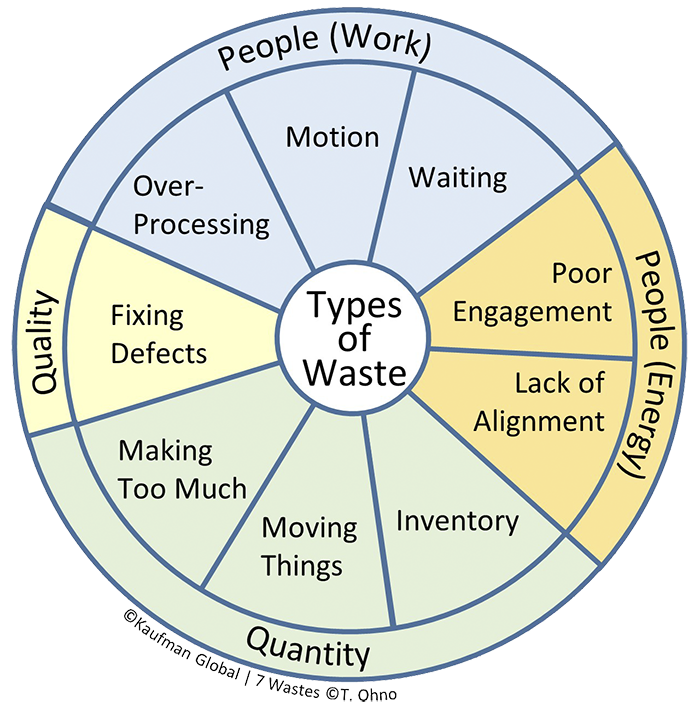

Kaufman Global modified waste wheel – The 9 Wastes

We have a standard implementation and project management approach, but we adjust according to application. For example, batch, discrete and continuous flow operations typically behave differently. Consider also build-to-order versus build-to-stock. Inventory mitigation and maintenance are critical success factors.

Kaufman Global has worked with hundreds of clients since the mid 1990s. Our proprietary methods: SLIM-IT ®, the Lean Daily Management System ® and the 20 Keys ® are in use around the world. Part of our Lean practice is developing Operational Excellence Leaders. In this work, we’ve developed hundreds of experts. Client include: BD, IR, Meritor, Schlumberger, Genentech, Avery Dennison, Goodyear, West Pharmaceutical and more.

We can help you speed results in manufacturing.

**********

Want to better understand the technical basics of Lean? Get our Implementing Lean Manufacturing white paper and learn about the evolution of Lean over the past half-century and why pull vs push is one of the most fundamental aspects of any Lean system.

Want to better understand the technical basics of Lean? Get our Implementing Lean Manufacturing white paper and learn about the evolution of Lean over the past half-century and why pull vs push is one of the most fundamental aspects of any Lean system.

Achieving Results and Teaching Clients How for Over 20 Years

Examples you say?

- Trained 30 Lean Leaders for an international automotive manufacturer with major projects at 4 plants in the US and Europe. Delivered over $20M in annualized benefits

- Implemented Lean for a global tire manufacturer with emphasis on locations in the US and Asia

- Conducted three flights of OpEx Leader training and drove improvement at 20 sites in the US, Asia and Europe

- Developed a global footprint strategy for a oilfield tool manufacturer and then implemented Lean at two facilities to improve productivity 30% globally

- Delivered a $30M business case for a multi-site manufacturer of industrial equipment with facilities in the US and Mexico