Making The Case for Value Stream Analysis

Value Stream Analysis or Straight to Implementation? That’s the question.

Complex operations problems are never solved by picking around the edges. Take a deeper view and do the examination that actually gives you the results you need.

Process Problems and Business Issues

Most process improvement techniques available today include some form of evaluation or assessment to baseline performance. This is good but it doesn’t replace analysis. Techniques like Rapid Improvement Events, workshops, A3s and even six-sigma’s DMAIC are mostly aimed at micro-, or best case, macro-processes. As such, they’re fantastic for fixing small problems using bottom-up methods and countermeasures, but they aren’t going to impact extensive value streams. Consequently, when these improvement techniques are applied as core practices to solve more complex, overarching business issues, the results often fall short of what actually could have been achieved.

People, geographies and data – important considerations for analysis

Value Stream Analysis – the examination of causes, effects and solutions – is a better starting point for macro and mega business issues. Typical targets include things like supply chain, sales and operations planning, consolidation, expansion, order-to-cash. Here, cross-functional and often tangled value streams are thorny and resilient. Addressing issues like these yields far greater results. Yet, these processes that are the fabric of the enterprise are often avoided to instead work on the pockets inside of them. This is because the modern organization promotes functional silos and when the inevitable push back comes, it’s simply easier to move on to something that can be more narrowly accomplished without attempting cross-functional cooperation.

Business Performance Fixes | Two Approaches

There are two ways to move forward: Direct to Implementation or Value Stream Analysis then Implementation. With direct to implementation, after some process evaluations or organizational surveys have been done, the decision to proceed is fueled largely by instinct and intuition; capacities proven to be seriously flawed in human beings. Conversely, with analysis, instincts and emotion are continually challenged with facts and data because change management is included in the analysis. Both ways can work, but be aware of the decisions you’re making when you go one way or the other.

Anyone tasked with improving business performance needs to manage risks and expectations. So it’s good to state the expected results at the start. With a narrow focus, there are fewer expectations and less risk – it feels safer. If goals are bigger and bolder, then doing some more thoughtful analysis and implementation design is essential. In this, the biggest problem to be solved isn’t the technical description about how results will be achieved – this is straightforward. Rather, gaining consensus about the path ahead is the most important outcome.

Direct to Implementation

This happens frequently. Sometimes process improvement itself is the objective. Here, the idea is to conduct a series of workshops, value stream mapping, training and such. Often, we’re told that for smaller direct to implementation projects, the business case isn’t important. We have never, no not even once, found this to be true. Business results are always important and inevitably someone is going to ask for them. Be ready.

Direct to implementation requires a lot of faith that process improvement will roll quickly to improve business performance. But, compared to what? Here, pay special attention to the starting conditions – the baseline. This makes measuring any improvement that follows a little easier. For example, if you’re working on solving a quality problem, be sure to understand the current level of defects and their cost, what reducing them would be worth and how any improvement becomes obvious and visible.

If direct to implementation is the only option on the table, then it should follow a specific pattern. If any of these steps are missed – particularly the steering team, there will be trouble.

- Steering Team formed and actively engaged

- Target Ideas generated via interviews and team working sessions

- Simple, prioritized opportunity list from impact-difficulty session with baseline performance data provided by the target areas

- Metrics identified and documented. We call this the metrics dashboard. It’s a baseline measurement of key performance indicators

- A plan that connects implementation activities with target opportunities

- Implementation with a sequence of activities intended to affect the performance baseline

- Monitoring and adjustment of the performance dashboard throughout the project – and beyond

Value Stream Analysis and Implementation Design

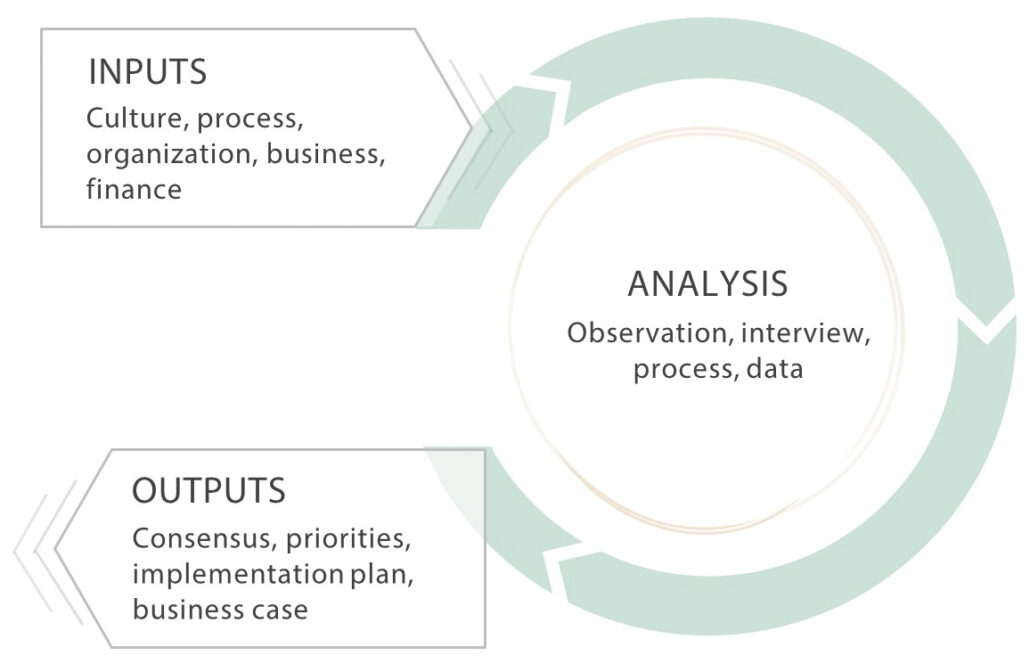

Analysis and Implementation Design Cycle: functional, operational, behavioral and financial inputs deliver a doable implementation roadmap

If you have the option, or maybe more importantly, if your issues are big enough that they warrant an up-front understanding of specific results and, you suspect you’ll encounter functional boundaries with numerous stakeholders then; start with an analysis. This is a highly accelerated mini-project. The deliverables are informed clarity, organizational alignment and mobilization, a time-based action plan and a business case. It follows these basic steps:

- Governance – Steering Team formed that lasts through the project (and beyond)

- Targets and opportunities developed via interviews and working sessions

- Solutions attached to business performance objectives and metrics

- Everything tested with data and analysis — including financials

- Direct observation of measured work processes

- Process decomposition (mapping, measurement, and lots of other analytics) – to connect specific improvements to business performance

- Final report and decision for a go-ahead to implementation

This is a cycle with numerous inputs validated against data and consensus. As new information emerges, it’s evaluated again, and again, until well-informed, well understood and potentially big decisions can be made.

The Steering Team meets every week for review, discussion and re-direction as necessary. This keeps stakeholders actively engaged and informed throughout the entire process — the surest way to enable consensus.

With an Analysis you get:

- Less ambiguity and an up-and-running governance structure (the Steering Team) to deal with any obstacles and barriers to progress that arise

- Strong consensus across the organization — especially with the leaders who must champion it, and,

- A validated business case; the reason for doing any of this in the first place. A business case is an “if-then” statement: “If we do these things, then we will get these results in this time.”

Either Way, Make a Plan

You might be thinking: What’s the difference? There’s a business case – or at least a result – for both. Keep in mind:

With Direct to Implementation, results are going to be less strategically chosen and less impactful. Cross-functional boundaries are harder to breach and the business case is lagging because it is stacked up during the implementation work. There is more inherent risk because of the ambiguity that persists with the “We’ll figure it out as we go,” trajectory. Without the structure prescribed from an analysis you’ll need to watch for waning resources and organizational focus.

With Value Stream Analysis then Implementation, results bear greater fruit with higher confidence. The business case is predictive and validated within the project work. The team-building, fact-finding and planning that are part of analysis makes results from implementation more prone to happen because expectations and the steps required to achieve them are completely, explicitly and thoroughly vetted. In other words, less risk for all stakeholders.

Sometimes you have no choice, the only way to start fixing things is to start small and work within a confined process, organization or functional boundary. If this is your best option for taking action, do it! On the other hand, if you have the ability dig into the more complex and interesting problems of extended value streams, be bold and begin with an analysis.

It’s ok to be bold sometimes.

If you want any help on filling in any of the details beyond a 1000-word blog post, you know where to find us.

Over the past few years, we’ve observed that clients want answers faster than ever before. And while it could be that “time is money,” it seems to us that it’s more related to the frenetic pace of, well, everything these days. Headlines and “apps” often don’t dig deep enough and the “Ready, Fire, Aim” approach has great potential for missteps.

Over the past few years, we’ve observed that clients want answers faster than ever before. And while it could be that “time is money,” it seems to us that it’s more related to the frenetic pace of, well, everything these days. Headlines and “apps” often don’t dig deep enough and the “Ready, Fire, Aim” approach has great potential for missteps.